Choosing lights is one of the most important decisions that farmers make when planning and setting up farms.

After all, lighting is responsible for a large percentage of both CapEx (capital expenses, or “upfront” costs) and OpEx (operating expense, the cost of running the equipment).

Lighting is also directly tied to production, and most farmers want to give the best light to their plants. Growers usually approach the lighting choice with both costs and production in mind.

Unfortunately, hasty decisions often leave other factors, like efficiency, by the wayside. This can lead to unexpected consequences that limit farmers and set them up for losses in the long run.

Dr. Nate describes the factors of a well-rounded decision for two of the most popular crop lighting options: HID (high-intensity discharge) and LEDs (light-emitting diodes).

HID vs LED: Making a balanced lighting choice

HID: Low CapEx, but limited efficiency and innovation

HPS (the bulb on the right in the picture below) is high-pressure sodium, one of the most commonly used HID lights in the world. A few pros of HPS lights are:

- The CapEx (capital expense, or upfront purchasing costs) is low because they’ve been on the market for decades.

- They have good spectrum for most indoor growers and can be used with a wide range of crops.

- Light is emitted in a more full spectrum that penetrates the plant canopy better than very targeted wavelengths.

HPS lights produce wavelengths more in the yellows, greens, and reds, so they have a very warm color to them. This means that they’re great for vegetative growth.

Metal halide is another type of HID lighting which runs slightly bluer.

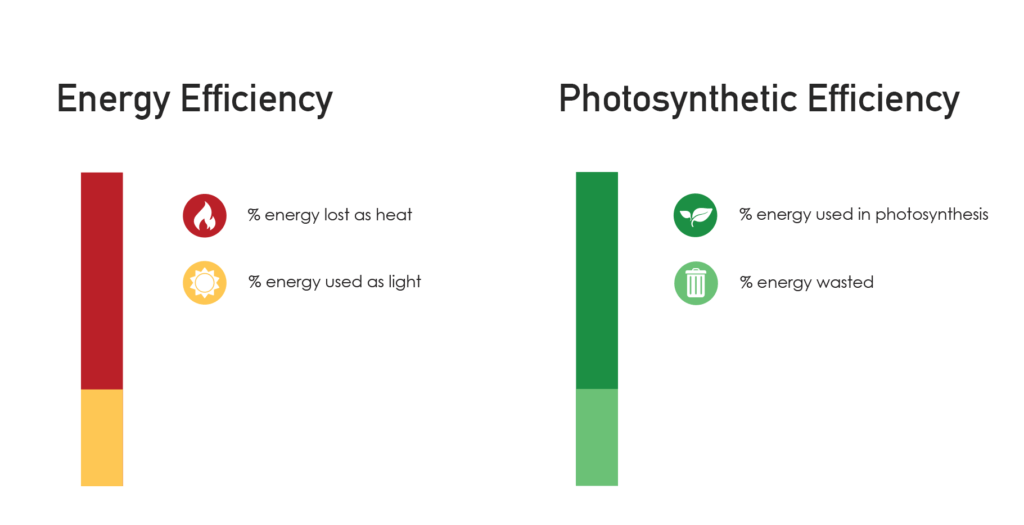

The difference between metal halide and HPS lies in the efficiency. There are two main types of efficiency that growers are concerned with when they buy lights: energy efficiency and photosynthetic efficiency.

Energy efficiency asks the question, “How much of the electricity put into the lights is turned into light as opposed to heat?”

Photosynthetic efficiency asks a different question: “How much of the light produced can be used by the plant in photosynthesis?”

The energy efficiency of metal halide lighting is roughly equal to that of HPS, but most people go with HPS because it is slightly more efficient in terms of photosynthesis.

The drawbacks of HID lights are:

- We’re nearing the end of the leash on cost reduction. Up to now, improvements have focused on lowering CapEx, and not much room is left to improve OpEx.

- They produce a lot of heat, so they don’t do great indoors, where heat accumulation is a real problem.

- They aren’t good in tight spaces. Because they produce more heat, HID lights can’t be run too close to the canopy. This means more space between crops and lights.

Overall, the most cost-effective application for HID lamps is as supplemental lighting in greenhouses.

That said, growers can’t know what the best lighting type is until they crunch the numbers for their specific situation.

LED: High CapEx, but versatility and a bright future

The other lighting type that we’re going to talk about is LED. If you’ve watched our other videos, you know that we believe that LEDs are the future of lighting. Here’s why:

- The CapEx costs are coming down quickly. With better manufacturing and more consistent materials due to volume, pricing and implementation costs are decreasing.

- The overall costs after a couple of years often come out ahead of HID. (Even though CapEx are typically higher, OpEx is much much lower.)

- They are energy efficient. LEDs produce more light to heat per unit of electricity used—about twice that of HID lights. This is important to indoor growers, who already struggle with the heat. Being able to reduce that means that we have to invest less in HVAC.

- LEDs are a bet on the future. The costs are trending downwards for LEDs and progress is speeding up. In comparison, HID lighting innovation has practically flatlined.

Of course, in some situations where heat removal isn’t a big problem, HID can still be better. See the questions below to work through the needs of your situation.

Although LEDs are much more energy efficient than other lighting types, they aren’t 100% efficient. Some energy is still lost as heat. This means that regardless of HID vs LED, you’ll want to have some kind of plan for dealing with heat.

2 solutions for dealing with heat

Over the years, growers have used a few ways to deal with that heat before it becomes a problem.

One way to deal with heat produced is using an HVAC system.

HVAC moves, removes, and conditions the air in the system. A well-designed HVAC system can do wonders for growing environments. Unfortunately, sizing and running an HVAC system requires a significant portion of the budget to be effective.

A second way—and our preferred method—is water cooling.

Water is better at absorbing heat than air, and using this more efficient heat removal makes the efficiency of the system overall go up. This also means that we can pull more heat away from the lights themselves which does two things:

1) gives them a higher lifespan and

2) allows us to get the lights very close to the plants.

These are all things to be thinking about when you’re choosing lighting for your farm.

Ready to start planning?

Before you do anything else (including researching equipment options!), define your needs and constraints:

- How close do you want lights to the canopy?

- How will you be removing heat from the area?

- Do your plants need more than just top lighting?

- How high are your electrical costs?

- Do you want to minimize your CapEx or your OpEx?

- Does my lighting choice balance costs and productivity?

Learn about these lighting issues in even more depth

When it comes to artificial lighting, things can get confusing in a hurry.

how about posting the brand names and model numbers of the lighting systems used?