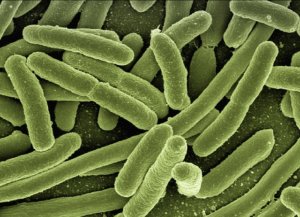

On April 10, 2018, an E. coli outbreak in the US was reported to the CDC. By April 9, 17 people were already infected. At the time this blog was published, there had been 149 infected people from 29 states, 64 hospitalizations, 1 death, and zero recalls.

Foodborne illness outbreaks are largely preventable by practicing food safety. While accidents happen, there are many things you can do to prevent contamination and thwart illness before it ever has a chance to reach your customers.

Foodborne illness outbreaks are largely preventable by practicing food safety. While accidents happen, there are many things you can do to prevent contamination and thwart illness before it ever has a chance to reach your customers.

Making someone sick can have serious consequences. Did you know that listeria can cause paralysis and even blindness? That salmonella can cause chronic arthritic pain?

Contamination is a risk in every step of the process, from production to preparation. While farming indoors with controlled environments and little to no risk of animal contamination can mitigate many food safety concerns, it is still an important issue to consider.

Here are the top things to consider when involved in selling or producing commercial produce:

(These are suggestions, so please make sure to consult your state and federal regulations before selling any produce.)

Hygiene

Making sure that you and your employees practice good hygiene, especially before entering the farm, is momentous in preventing contamination.

Hands—to avoid contamination, wash hands thoroughly for at least 30 seconds and wear gloves when handling produce. This doesn’t mean those flimsy, scratchy, cloth gloves you get from Ace Hardware for gardening. It’s a good idea to get one-use, latex-free (to avoid allergens) nitrile gloves. Dispose of them after each use.

Hands—to avoid contamination, wash hands thoroughly for at least 30 seconds and wear gloves when handling produce. This doesn’t mean those flimsy, scratchy, cloth gloves you get from Ace Hardware for gardening. It’s a good idea to get one-use, latex-free (to avoid allergens) nitrile gloves. Dispose of them after each use. - It is also good practice to keep children out of the farms—kids can be pretty messy. If you’d like your farm operation to be a family activity, make sure that your kids follow the same hygiene principles that you do.

- Keep animals out of farms at all times. If there has been evidence of animal activity, you will need to investigate and possibly dispose of produce.

- PPE (gowns)—Dedicate “clean suits” for yourself and employees wear inside your farm. These could be reusable or disposable sanitary gowns or coveralls that you wash frequently. Consider wearing hair nets, beard nets, and sleeves for extra protection if/while packaging.

- Leave food and drink outside the farm. In addition to potentially carrying unwanted bacteria, external food and beverages may bring allergens into your farm that could pose risks to your consumers. Leaving them out of the farm all together will help avoid that risk.

- Minimize the number of personal items allowed in the farm. This includes cell phones, jewelry, nail polish, hair extensions, and even band-aids. These things can fall or chip off into the produce, and often carry bacteria. If you do need to wear a band-aid, make sure it is properly secured and covered with a glove, sleeve, etc.

- Keep ill employees out of the farm until you are sure there is no risk of contamination. Good practice is to keep them out until at least 24 hours after symptoms end.

Supplier Control

You probably rely on external suppliers for many items within your farm; from structural components to system inputs. Any one of these could potentially harm your product, so choose very carefully where you get your supplies.

-

- Is the company reputable?

- Have you looked into their processes and/or systems?

- What food safety protocol do they follow?

- How will they notify you of a recall?

What about your seeds, plugs, trays, lights, and even nutrients? Are they guaranteed to be safe? When possible, get a letter of guarantee for each of the items supplied to you by an external supplier. This is your opportunity to make sure that all of your supplies meet your high standards for food safety!

Traceability

If one of your plants becomes contaminated, it’s likely that the plants surrounding it are also at risk. Traceability allows you and the consumer to identify where in each plant’s life cycle they may have been put at risk. Consider tracking each plant from seed all the way to packaging and sale. You don’t have to track each and every seed, but you should track from which supplier the seeds came, and from which package. This could be a life-saver if a plant was contaminated as a seed before it even reached your farm.

In addition to seeds, track the other items in your supply chain. For example, document which tray held each seedling and where that tray came from. An easy way to do this is to assign each system component a name, a number, or a combination of the two. Use a spreadsheet or a traceability software to keep track of them. This way, if one of your consumables has a recall, it’s easy for you to identify where and how you use it in your farm.

Recall program. Recall programs are often implemented in very large-scale commercial food service companies and are used to remove product from the market that has been identified as being potentially harmful to consumers. Unless you are a large commercial supplier, you probably won’t be too involved in this.

Sanitation Program

- Tools—make sure that your tools are cleaned before and after each use. Also, ensure that any cleaning supplies such as brooms and mops are specifically designated to the farm. A regular household mop could bring in any number of outside contaminants!

- Make certain that the way you transport your produce is sanitary, and minimize the likelihood that customers could handle the food before purchasing.

- Have a process in place for sanitizing and sterilizing all system components before and after each crop cycle. Make sure you use food-grade chemicals so you don’t kill your plants or your customers!

GAP/GMP

GAP: Good Agricultural Practices. These ensure that your grow operations encourage a food-safe environment. GAPs make sure that the way you grow your produce is safe and clean. These are often required by grocery stores, so if you plan on entering that market, make sure to ask if they’re required. We recommend that everyone who sells produce acquire a GAP certification.

GMP: Good Manufacturing Practices. These are requirements you must meet to ensure that you produce safe food, and focus on the food processing at your farm. This means harvesting and anything that happens to the produce after. These practices track the quality of almost everything that happens in your farm, including your system components and processes.

Additional Considerations

- Allergens—when dealing with foods, make sure to state which allergens may have come in contact with your produce, and which allergens are concurrently produced at your facility. Also, consider which allergens you bring into your farms by handling them; You don’t want to make someone sick because you ate a peanut butter bar and then touched the produce you sell.

- EMP or Environmental Monitoring Program helps manage the conditions that could encourage the growth of microorganisms that cause foodborne illnesses including how effective your sanitation and hygiene programs are.

- Storage temperature. Produce needs to be kept cool after harvest in order to keep it from accumulating or growing bacteria or diseases. The food-safe temperature is 41º F or below. If produce is brought below this point and then rises above again in temperature, the risk of contamination is increased, and the food is unsafe. If you will be harvesting a long time before selling your produce, consider implementing cold storage.

Conclusion

Whether it’s just you running your farm or you employ helpers, you need to make sure that everyone entering your farm is aware of the food safety risks and the tools they can use to prevent illness. Though there is more concern when you’re selling your produce to a market, you should also keep good food safety practices if you run a small hobby system at home. You can ensure that your produce is safe for consumption and keep your consumers healthy by employing food safety tactics in your farm.

“About 48 million people in the U.S. (1 in 6) get sick, 128,000 are hospitalized, and 3,000 die each year from foodborne diseases, according to recent data from the Centers for Disease Control and Prevention. This is a significant public health burden that is largely preventable.” — FDA FSMA https://www.fda.gov/Food/GuidanceRegulation/FSMA/