Takeaways:

- The first line of attack for cooling a greenhouse is ventilation. (0:54)

- There are two types of cooling: evaporative and mechanical. (2:30)

- Humidity can be controlled by using either refrigerants or desiccants. (9:02)

- Heating is more common in greenhouses than in indoor or vertical operations. (12:19)

- Air circulation is important for vertical farms and greenhouses, but it can be very challenging. (15:22)

- There are several ways to filter or purify air, although some can do more harm than good. (18:40)

This lesson topic will be a brief overview of some climate control systems. This will give you a better idea of what people are trying to sell to you or are recommending.

Ventilation

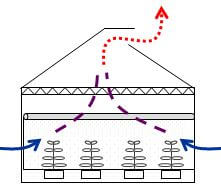

Ventilation is the first line of attack when trying to cool a greenhouse, and entails exchanging indoor air with fresh outside air. There are two types: mechanical cooling and natural cooling.

1) Mechanical cooling, which employs large fans.

2) Natural cooling, which use wind and buoyancy to let air escape from the facility. Natural cooling can be highly unpredictable depending on wind direction. This unpredictability leads to the questions; what is the best orientation? At what wind speeds are velocity and uniformity maximized within the greenhouse?

Cooling (evaporative)

Hot climates with low humidity can use evaporative cooling. There are three methods:

Wet pad – There is a wet pad at one end of greenhouse and a fan at the other, which sucks air from outside, draws it across the wet pad, and causes the temperature to drop and humidity to increase. The air then moves across the greenhouse, picking up moisture and rising in temperature as it moves from one end to the other. Another name for this is an evaporative cooling wall. (Learn how to build a DIY cooling wall for your greenhouse in this video.)

High-pressure fog and low-pressure mist – These work by injecting water into the air where you’re growing plants. In theory, this works great to get the cooling everywhere in the greenhouse, but it is challenging because the temperature and humidity around the plants tend to be non-conducive to evaporation. When you have high humidity around plants, it can interfere with transpiration.

High-pressure fog tends to work a little better than low-pressure mist because it uses smaller water droplets, which evaporate easier.

Cooling (refrigerant-based)

Refrigerant based or mechanical methods for cooling are not dependent on evaporation. They can be employed in a greenhouse, a warehouse, or a vertical farm operation.

Heat pump – Heat pumps are basically air-conditioning. A small outdoor box delivers refrigerant to coils inside the building. These have fans which circulate the air, pick up heat, and send the refrigerant back to the outside unit which then ejects the heat to the outside.

Packaged DX – This is one large unit that incorporates all of the elements of equipment into one box: the compressors, condensers, coils, fans, controls. Everything is in one piece of equipment outside of the facility. This is great because maintenance of the unit doesn’t require you to disturb your plants in order to get to the components. Heating can also be incorporated into this unit.

Chiller with air handling units – This is a more complex option. In a chiller, the refrigerant cools water instead of air. The water gets piped to the facility and air handling units. The air handling units have coils for the cool water and fans that blow air around. Refrigerant picks up heat from the air, returns to the chiller, and it chills the water again. Dr. Nadia recommends these only for larger systems because of its complexity and higher need for maintenance. It also requires more infrastructure.

Dehumidification

A lot of people have moisture challenges. There are a few ways to mitigate moisture and reduce humidity. Some of these are:

Refrigerant – First, we can use the same refrigerant based systems from air conditioners for dehumidification. We can do this by producing refrigerant or chilled water at such a low temp, below the dew point, that we can extract moisture from the air through condensation. This air can then be returned to the space.

Desiccant – Second is using desiccants. Desiccant units can get huge, and they are filled with something like cat litter. This absorbs moisture through a chemical process. For more on liquid desiccant dehumidification, check out the humidity course with Kurt Parbst.

Heating – Third is heating, also with desiccants. When dehumidifying by heating, the moisture is extracted, and the heat that is being used to recharge the desiccant is getting pushed back into the greenhouse space. The combination of removing moisture and heating the air will have a dehumidification effect.

Heating

Heating is generally done after cooling to extract moisture, making it much more common in greenhouses.

What are the most common heating methods?

Hot water boilers – Boilers deliver hot water to heat pipes or radiant pipes (radiators) throughout the greenhouse. Hot water can also be sent to air handlers and controlled through the same packaged unit as is used for cooling.

*As a side note about carbon dioxide enrichment, you can use the boilers (only natural gas and condensing boilers) to enrich carbon dioxide as well.

Learn about wood burning boilers here.

Gas furnaces – Gas furnaces employ a unit heater in the greenhouse, to which you’re piping natural gas or propane As it burns the gas, the heater produces heat right there in the space. Always vent propane because it produces a lot of potentially hazardous gasses.

Infrared heaters – Infrared heaters use light waves that we can’t see, but that produce heat. These waves heat surfaces when the light is absorbed by that surface. Infrared heaters don’t dry out the air like many heaters do.

Heat pump – You could actually use the same heat pump used for cooling. By reversing the flow of the refrigerant, the heat gets pushed into the space as opposed to outside the space.

Air distribution and circulation

How can we improve air circulation in vertical farms and greenhouses? Stagnant air and poor circulation can cause serious problems when heat and humidity accumulate. This is one of the top challenges for indoor growers!

Circulating fans – Fans don’t always send air uniformly across the greenhouse. A lot of cool moist air gets delivered to one end of the greenhouse, and as it travels across the area, it picks up heat and moisture, so there is not a uniform climate.

Ducting – Ducting is a very effective method for distributing air throughout the facility, and helps provide a more uniform climate. You can punch holes in the ducting to create more

mixing. Ducting can also be used for vertical farms!

Fan coil units – Dr. Sabeh is not particularly fond of fan coil units because of all of the equipment that’s in the space. That said, if you’re distributing the units within many locations, you are creating a more uniform climate.

Air filtration and purification

Particle filters: – Particle filters are similar to the ones that are in homes. In air conditioning units, they have a MERV rating that allows certain sized particles through the filter.

Adsorption: carbon filters – Carbon filtration would be a method to use if you are concerned about odors or volatile organic compounds. It uses a chemical process to adhere those compounds to the filter.

UV sterilization – UV lamps can be very effective, but only if you can increase residency time in front of the lamps. They will have no effect if the air doesn’t spend adequate time exposed to the UV.

Ozonation and ionization – These have very questionable efficacy. ASHRAE, or the American Society of Heating, Refrigerating, and Air-Conditioning Engineers, did a study on the effectiveness of different methods of air filtration and purification. They found that there wasn’t enough evidence to prove that ozonation and ionization work that well. In fact, they produce harmful byproducts, which may be more harmful than those that you are trying to remove. Check out the paper here.