How do you measure the value of LEDs? Efficiency.

Anybody with an eye on the tech industry has noticed the rise of LEDs. In farming, they have been accepted—or rejected—with varying opinions. Many traditional lighting users write off LEDs due to their high capital expense while others praise high efficiency LEDs as the way of future farmers.

The truth is, LEDs are fundamentally different from other lighting types and can even exhibit influential differences among themselves. Each difference in the form and function of LEDs impacts the most important factor of farm lighting: efficiency. But what does that efficiency could look like, and how could it change the farmer’s lighting decision?

Form and function of LED lights give them great potential for efficiency

In an LED (light-emitting diode), electricity flows through a semiconductor. Some of that electricity is converted into heat, and some of that electricity is converted into light. (More on this in the downloadable lighting guide.) Depending on what type of semiconductor is in the diode, a very specific spectrum of light is emitted. That specificity is very important to wavelength or spectrum efficiency.

Another fundamental characteristic is that many small diodes—encased in plastic caps not much larger than a pinhead—make up one LED lighting array. This allows for versatility in size and shape and opens up even more opportunities for efficiency. This versatility also affects the repair process for lights.

Learn more: Get the Modern Farmer’s Guide to Indoor Lighting (for free!) here.

3 facets of lighting efficiency

There are three types of efficiency that contribute to choosing high efficiency LEDs: spectrum (wavelength) efficiency, equipment efficiency, and form factor.

1. Wavelength efficiency

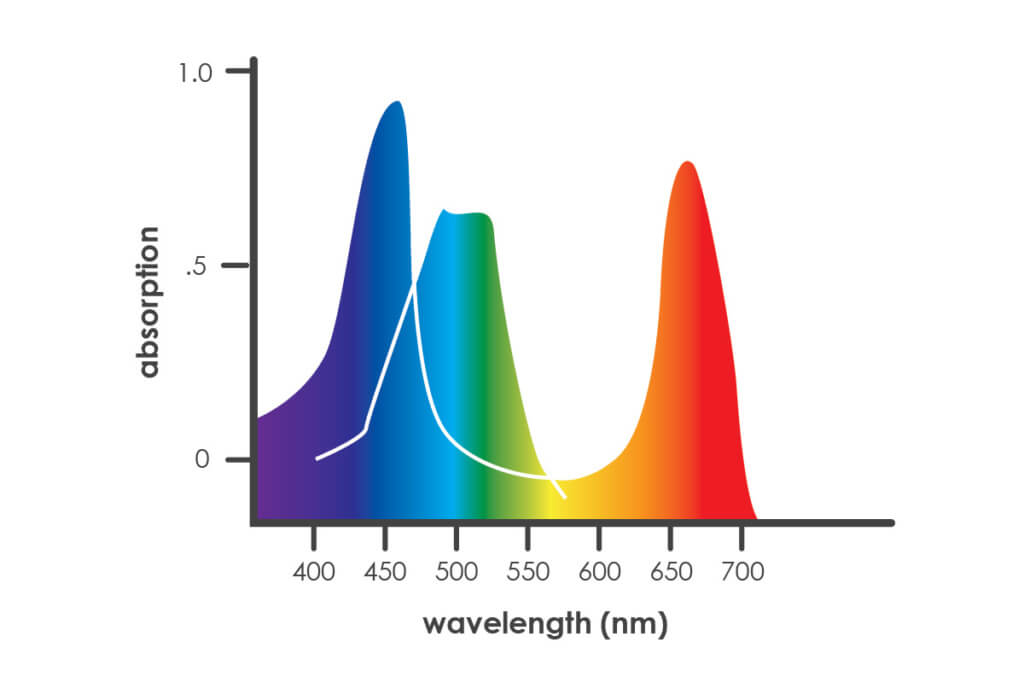

The ability to deliver very specific wavelengths to our plants is important because plants absorb light in a specific range. By targeting that specific range, less light is wasted—we aren’t emitting wavelengths that the plants can’t use.

Different plant pigments take up light at different wavelengths. Here you can see plant absorption levels of different wavelengths.

2. Equipment efficiency

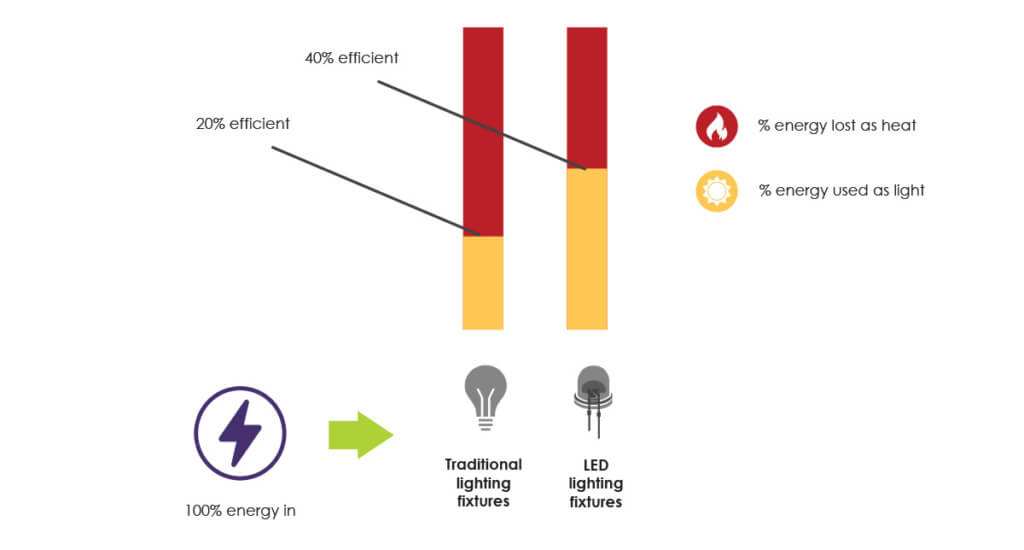

Equipment efficiency describes the amount of electricity that is converted into light, and is usually stated as a percentage. LEDs usually reach somewhere between 40 and 50% efficiency, meaning that 40–50% of electricity put in comes out in the form of light.

To put that in perspective, a top-notch HID light would see about 25–30% efficiency. For example: if you switched from a typical 600-watt HID light to a 300-watt LED, it would produce about the same amount of light. Remember that since we’re emitting a very specific spectrum, we’ll see another bump in productivity on top of that.

To put that in perspective, a top-notch HID light would see about 25–30% efficiency. For example: if you switched from a typical 600-watt HID light to a 300-watt LED, it would produce about the same amount of light. Remember that since we’re emitting a very specific spectrum, we’ll see another bump in productivity on top of that.

A common misconception is that LEDs don’t produce heat. They do. For each watt being put into an LED, about 3 BTUs (British Thermal Units, an important unit for calculating heat removal) are produced.

3. Form factor

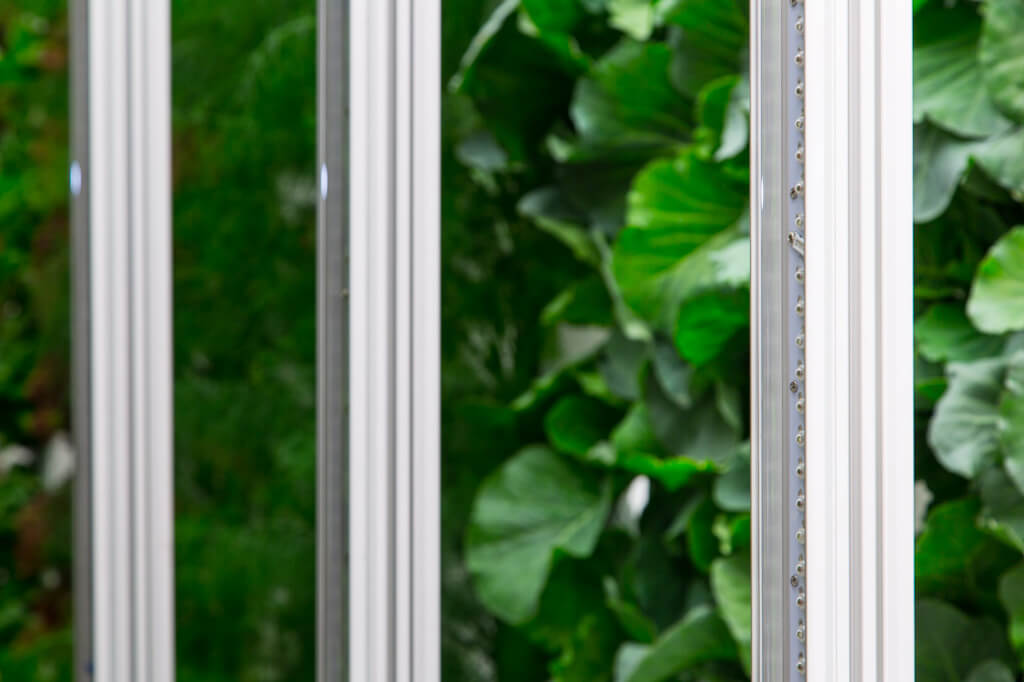

The form factor is how light is configured and integrated into the farm. It determines how close you’re able to put the light to the crop and how it uses space in the farm. Three main form factors are panels, fixtures (box-shaped), and bars.

Each form factor has pros and cons—for instance, fixtures typically featured air-cooled LEDs with high intensity, while bars, so far, have only been able to offer low intensities.

Other key factors of lighting efficiency

Intensity affects cooling and cooling affects lifetime

While LEDs produce less heat than other lighting, they still produce heat. This is extremely important to know, because when an LED heats up, it produces less light. The cooler you keep LEDs, the better they will perform.

Not only does heat negatively affect the efficiency of LEDs, but it reduces their lifetime. As you can see, heat has a bad relationship with efficiency, light intensity, and lifetime.

Power supplies have their own efficiency ratings

A power supply is the component that converts an alternating current to a direct current. In other words, it converts the incoming power so it can be used by your lighting equipment. Usually, if you buy lighting as a system, the power supply will come with it. Otherwise, you can find information about the power supply from the power company that you’re using.

Power supplies usually have an 80–95% efficiency rating. That means that 5–20% of the incoming power is lost from the power supply as heat. To minimize heat loss from your power supply, go with the higher efficiency rating.

Make sure you aren’t wasting all that planning with bad coverage

Coverage is the last thing that affects efficiency. Good coverage is possible when the lights are evenly spread across the face of your plant canopy (this is harder to do with box lights and easier to do with bars) and when they are close enough to the canopy.

Most traditional lights are limited by distance to the plant canopy due to heat that can burn plant leaves. LEDs can be placed closer to the plants than other lights because they produce less heat. LEDs can be right up next to the plants with proper cooling and airflow.

Regarding “waste heat” – are there any ways of reclaiming the heat produced by LEDs and recycling that energy for some other use?

Hi Jonathan, good thinking there! A few options for reclaiming that heat would be installing heat exchangers downstream of the lighting, or using heat pumps.

yes !- watercooled system – soon to be see in lumen-laden

Nice info. It is a bit technical but easy to understand.