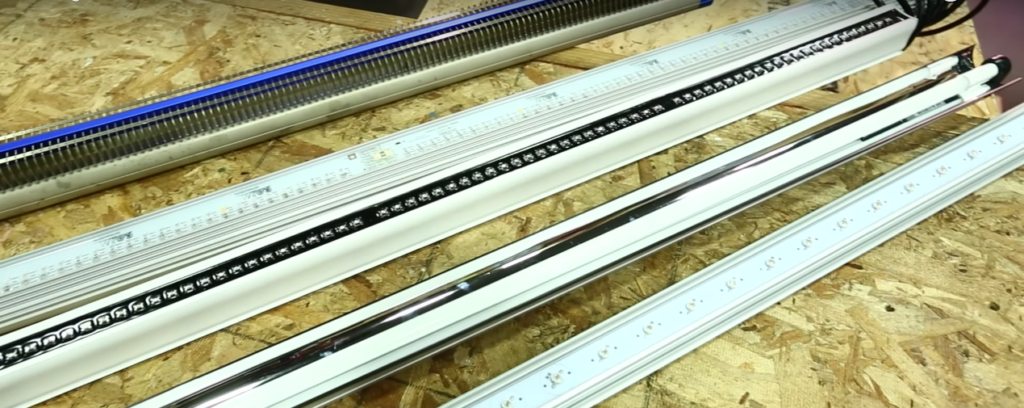

The rise of light bars

LED light bars provide farmers with good coverage and flexibility, although light intensity can suffer.

![]() Light intensity refers to the amount of light energy transferred from the light source to a surface, and it can be measured in several different ways. Useful measurements for farmers include the amount of useful light delivered to a surface per a unit of time, and from a defined distance.

Light intensity refers to the amount of light energy transferred from the light source to a surface, and it can be measured in several different ways. Useful measurements for farmers include the amount of useful light delivered to a surface per a unit of time, and from a defined distance.

Light bars have proven to be the lighting of choice for many indoor farmers, and they look to stay that way because of their versatility in use and coverage.

Of course, these benefits are complemented by the fast development of new lighting gadgets (like meters, cooling mechanisms, and remote controls), new lighting technology, and increased efficiency in lighting products. Of the variety of quality light bars on the market, each boasts its own interesting benefits, and many have a “next generation” already in development.

Of course, these benefits are complemented by the fast development of new lighting gadgets (like meters, cooling mechanisms, and remote controls), new lighting technology, and increased efficiency in lighting products. Of the variety of quality light bars on the market, each boasts its own interesting benefits, and many have a “next generation” already in development.

All light bars are marked by the shape that makes them applicable to almost any configuration and better at accomplishing equal coverage over a crop space. The leading light bars on the market, however, are placed there by how they justify light intensity with heat output. (More on why that’s a make-or-break factor below.)

Related Reading: 6 Types of LED Light Bars for Indoor Farming

Hang it, hook it, perch it, rest it—bars are versatile.

The light bar’s simple shape makes it easy to hang, hook, perch, or rest on almost any surface and at any angle. This is a huge strength in the eyes of high-density farmers, who often need to place lights in between, under, or parallel to crops.

Many farmers hang light bars horizontally, one over the other to look like a ladder, then use a pulley or hinged system to pull the lights out of the way for maintenance.

Others line up light bars vertically next to each other and daisy chain them together, then move them like a shower curtain. The ability to move the light bars out of the way means that the space used for lighting can be reclaimed as space for maintenance later on.

Growers using stacked beds can thread the petite bars between layers and pin them to the bottom of the beds above. Considering the alternative, – using bulky lighting fixtures, which require more space and more support – bars are a godsend.

Yes, there’s no doubt that light bars give indoor and vertical farmers a lot more freedom to use their space. Take that freedom away, and farmers are back to wasted space. But space use is only half of the benefit.

Line them up, row on row — bars offer better coverage.

The other appeal of light bars is the even coverage of light over a crop space. The long line form makes coverage as simple as stacking the bars one over the other. In comparison, fixtures shed a more square-shaped light coverage on crops, but since they are usually confined to a greater distance from crops, the edges of that square have more dispersed (dim) light than the center. This uneven coverage can lead to uneven growth.

The square shape sometimes leaves the edge of a bed or growing plane unlit as well, demanding that the farmer either add another row of lights and waste the light that hangs over the edge of the plane or accept yield reductions in that part of his space. (Imagine fitting wide pieces of cheese onto a piece of bread. It will either hang over the side, or the edges will be dry and cheese-less. Of course, when making a sandwich, this can be solved easily by tearing the cheese in half. With lighting, you have to switch forms.)

Bars sidestep this downfall with long, sweeping light coverage. Different lengths—two feet, four feet, six feet—are more available and bars can be stacked or lined up in rows.

The intensity-to-heat generation trade-off

In all their utilitarian glory, light bars do have one downfall: they’re limited to passive cooling.

With no space for the active cooling tools of fixtures (most LED fixtures have fans combined with a heat sink board to keep the light cool), light bars are chained to passive cooling. We believe that this will change in the future, but in the meantime, light bars are limited to heat dumping via heat sinks.

Without that active cooling, high-powered LEDs are at risk of damaging the light (not to mention frying the plants), so low-powered LEDs are used instead.

As a comparison, take the LumiGrow Pro 325, a great fixture used in – and perfect for – many applications. An LED board the size of a clipboard is 325 watts; a four-foot LED bar might be 150 watts, and achieve that power with an elaborate baffle system. Essentially, the LED light bar user sacrifices power for utility.

A bright future for LED light bars

LED light bars can be a great way for modern growers to keep their plants growing strong while operating indoors, especially when growing with vertical plane production. However, because of this streamlined form factor, light bars often have to trade light intensity/output for lifespan.

At the rate of innovation in the indoor agriculture industry present today, we see an even brighter future on the horizon when it comes to lighting. Maybe the sacrifice of intensity will be overcome, and growers will have access to further benefits from LED light bars. If there’s one thing we know about the pace of indoor agriculture, it’s that new technology emerges every single day.

For now, light bars remain the best option for high-density growers.

Can growers optimize light to get higher yields and lower costs?

Understanding the different types of lighting that are available, and how light interacts with plants helps farmers to increase efficiency and grow healthier, tastier crops. The Modern Farmer’s Guide to Artificial Lighting provides this information!

In this guide, you’ll learn:

- The pros and cons of all types of indoor lighting

- How light intensity is measured

- How light-emitting diodes (LEDs) work

- Considerations of LED form factors such as box, panel, and bar lights

Could you please list the brand names and model numbers of the lighting systems shown?

Hi James, more information here: https://university.upstartfarmers.com/blog/6-types-led-light-bars-indoor-farming

A way that I could see an improvement in their system is the improvement of the use of the space as the plant grows. WHILE THE PLANT IS SMALL, THERE IS A SPACE THAT IS SUBUTILIZED. IF IT CAN BE AUTOMATICED THAT THE ZIPGROW ARE SEPARATING AS THE SPACE GROWS AND THEIR SPACE IS BETTER, AS IS WITH HYDROPONIC FLOATING ROOT SYSTEMS, IN THIS WAY THE WALL AND THE LIGHTING SYSTEMS WOULD HAVE BEEN ADAPTED BETTER AS WELL AS THE LIGHTING SYSTEMS WILL REDUCE THE PLANT LIGHTED SPACE.