Takeaways:

- In addition to sizing setpoints, think about what design criteria the HVAC system will fill. (0:20)

- There may be constraints to consider in terms of design. (2:48)

- Using a ‘right-sized’ system will be beneficial both in function and financially. (4:45)

- It is a good idea to have an engineer design the system for several reasons. (16:54)

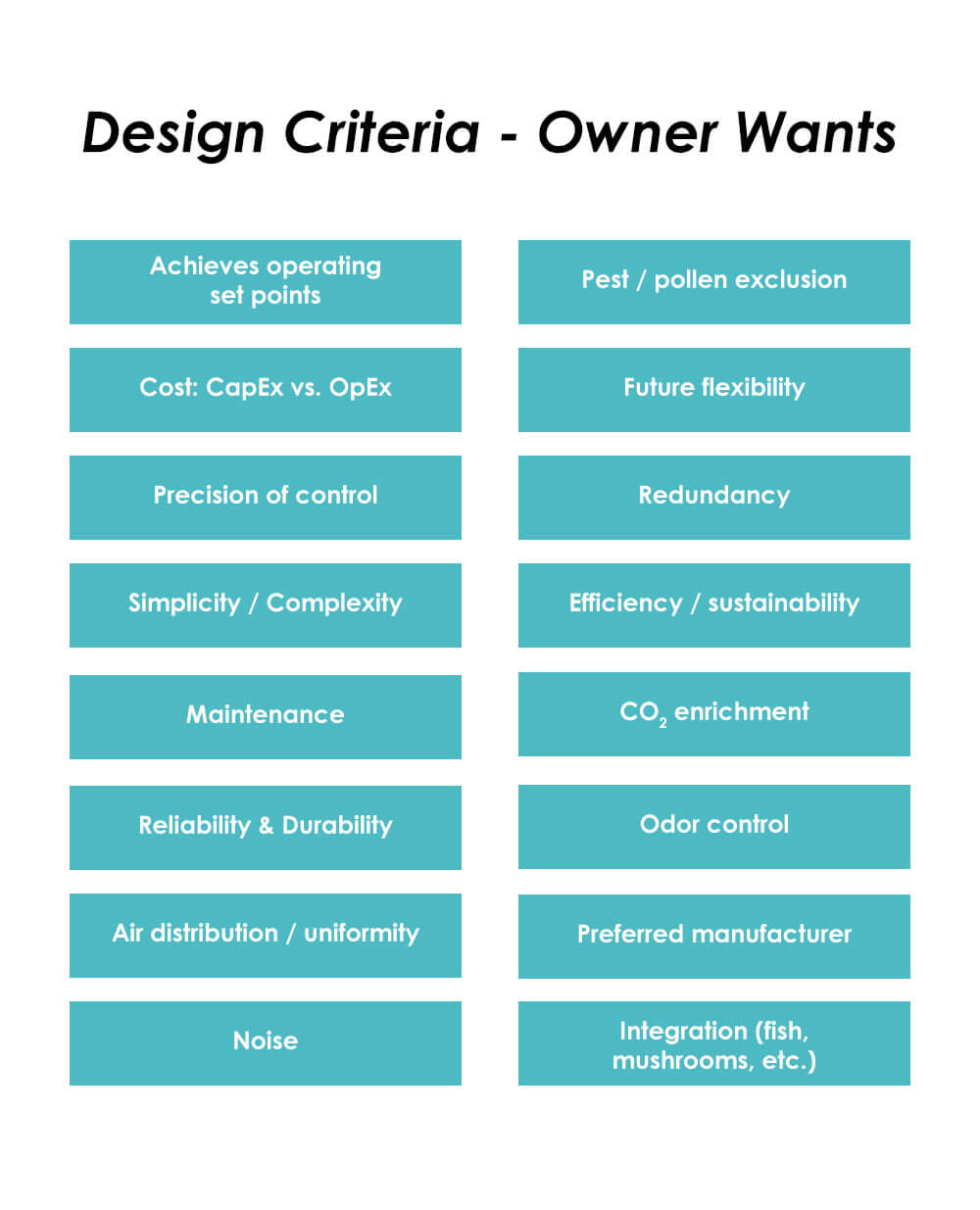

This lesson topic will cover design considerations. What are you trying to achieve beyond the setpoints of size? Consider these design criteria:

These are all part of the conversation when considering which HVAC system you want in your facility.

Design Constraints

Budget is the obvious constraint. There are other factors to think about as well.

Space – Where will you put the equipment? Do you have space for a chiller? Can your roof support a package system?

Structural limitations – How old is the building? Does the existing infrastructure support the system you need? What modifications will be necessary?

Utility service (electric, gas, water) – What is your electric panel size? What is the existing electrical service (consider your amps)? Do you have access to natural gas, or do you have to ship in propane? What about water; will you be using well or city water?

Utility rates – What are your operating costs? Do they realistically reflect utility costs?

Property line and neighbors – Do you have a restrictive property line or residential neighbors?

Codes and regulations – Think about things like the amount of energy that is being used by your indoor facility. How do you meet current codes and regulations, and how will you prepare for the future?

CapEx vs. OpEx

There is a balance between how much a system costs (purchase, install, design) and what it is going to cost in the future (utility, maintenance, replacement). The first type of cost is called capital expense (CapEx) and the second type of cost is operating expense (OpEx). This is a balance that every grower has to find when planning their system. To find it, growers need to prioritize reliability, controllability, satisfaction, and risk management.

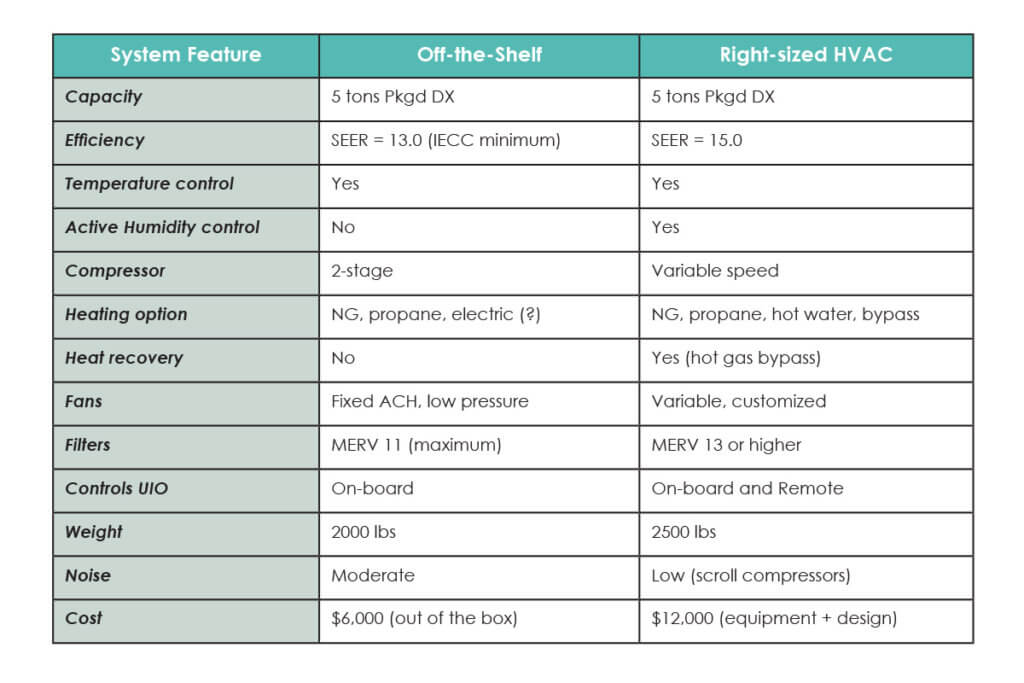

As an example, we are going to look at an off-the-shelf piece of equipment (low CapEx, high OpEx) versus a piece of equipment that has been designed for your needs (high CapEx, low OpEx). Let’s look at the differences:

Variable speeds for compression, customized fans, and finer filters mean that the right-sized systems will be much better fitted for your facility in the long run even though they’ll be heavier and more cost-intensive up front.

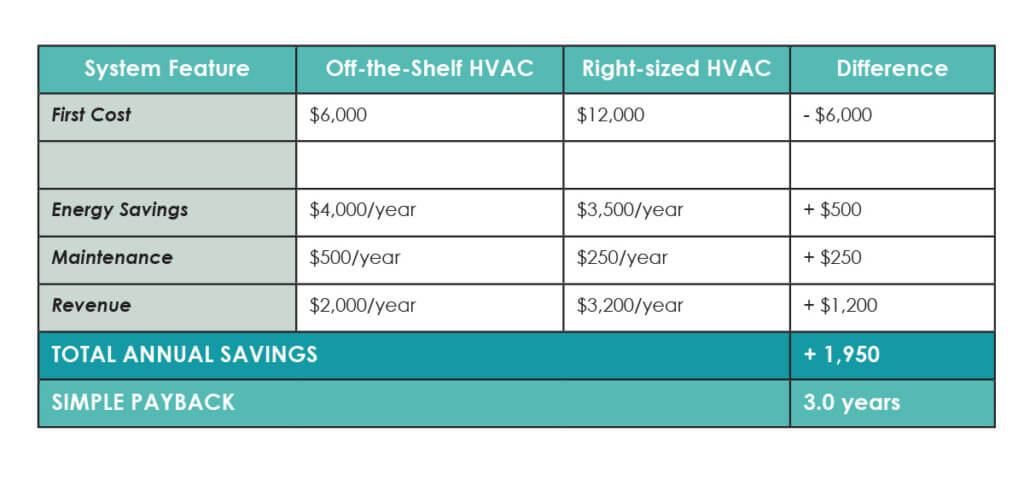

What is the value-add of the right-sized equipment?

Reduce operating costs

- Off-the-shelf – $4000/yr

- Right-sized – $3500/yr

- That is a 12.5% reduction in energy costs!

Increased revenue

- Temperature/relative humidity control; you get higher yields, healthier plants, and fewer losses.

- Growers consistently say that if they had better T/RH control, they could increase their sellable product by 20-30%. This also means that crop losses due to mold, non-uniform conditions, or equipment breaking down could be reduced by 10%.

- If you can manage the climate to get the crop responses that you want, you will get better quality, a better chemical profile, and a predictable product. You can actually ask for a price premium, and mark the price up by 20%.

Let’s look at the balance sheet between the off-the-shelf product and the right-sized product.

It may be twice the cost, but over time, as you can see on the chart, the savings will pay back quickly. The off the shelf units are not designed to operate at peak capacity 24 hours a day, whereas the right-sized units are. They will last beyond 5 years. This example is for 5 tons of cooling or 500ft2 of growing space. The annual savings for this little system is almost $2,000 and has a payback of 3 years. Payback timing is really up to you, some people want it in 18 months, some people are ecstatic with 3 years.

Why do you need an engineer?

Having an engineer design your system for you will be invaluable. You might be thinking, “But why can’t I do it myself?”

After working with dozens of indoor growers, Dr. Nadia has seen four major advantages in hiring an engineer to design your HVAC:

- Engineers understand your operating requirements. Engineers know what you need to do, and what your HVAC system needs to do to achieve the conditions that will optimize crop yields and your bottom line.

- Engineers design a complete and thorough system. An engineer is going to ask you questions about what is important to you, or what is constraining you.

- Engineers understand permitting and building codes. If you need a set of permit plans, an engineer can help put those together for you so you can get a permit and meet the codes.

- Engineers can model estimated energy use and costs. If looking at long-term operating costs for your specific facility is important to you, an engineer will work with you to build a model.

For those of you who are interested in growing tomatoes or any tall vining crop, Dr. Nadia’s book, Tomato Greenhouse Roadmap will be helpful to you to understand the process of planning. She also contributed two chapters to Plant Factory, published by Elsevier and headed by Dr. Kozai, who is a legend in the farming industry. If you are interested in reading her chapter on environmental factors (temperature, humidity, carbon dioxide etc), please contact her, and she can provide that to you as a resource!

520-609-8875

Nadia@doctorgreenhouse.com

That wraps up our HVAC design course! Thanks so much for watching and thanks again to Dr. Nadia Sabeh at Doctor Greenhouse for the great info. If you have questions on this presentation, please visit doctorgreenhouse.com to contact Dr. Nadia.

Please take the quiz at the bottom of this page and then the final quiz to receive your certificate.

Next, continue on to the Seeds and Seedlings course and get things growing! Before you do, we would love for you to take a moment to share your thoughts on this course and leave us a review. Thanks!