When GPH just isn’t enough, HP steps in

So you’re building a hydroponic or aquaponic system, and have done the calculations to size a pump. Let’s imagine that you’ve calculated your flow rates and decided that you need a pump capable of moving 2000 gallons per hour (GPH).

Most of the time, a GPH rating will help you find the pump you need. However, some pumps ditch the GPH rating for a horsepower rating (HP), and that’s when things get tricky.

For your 2000 GPH system, none of the submersible pumps you’ve researched will fit it. You’ve begun looking into larger inline pumps, but they’re all pumps sized in horsepower!

There is no easy GPH to HP conversion, so you are stuck with what seems like an obsolete GPH. What do you do?

In this article, we’re going to discuss the difference between GPH and HP rating, which pumps they apply to, and how to navigate pump sizing with both measurements floating around.

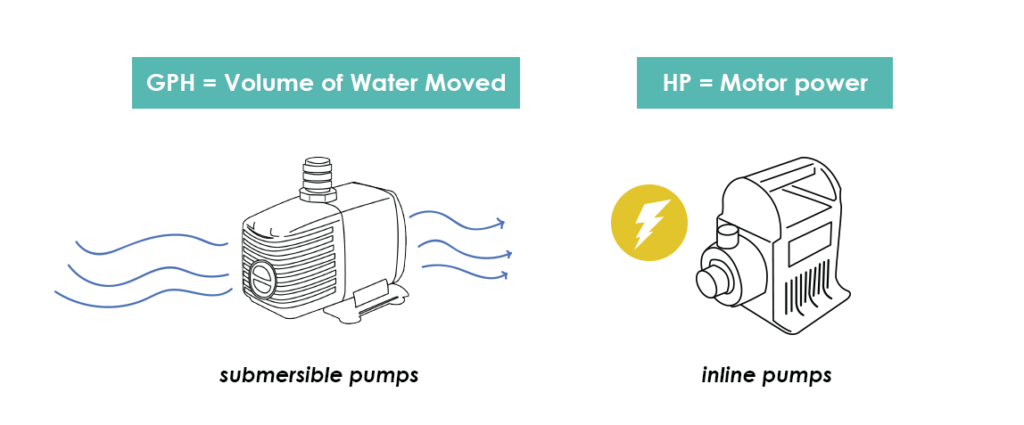

Volume moved vs. motor power

GPH and HP are talking about similar things. Horsepower is the power of the motor, and gallons per hour is the amount of water that the pump can move.

GPH ratings are used for smaller submersible pumps.

Most pumps come with a graph showing how much water a pump can move at different heights. For these pumps, using HP isn’t worth much; a lot of the time these pumps are only powered by a couple of amps. For larger pumps, the GPH ratings get so big that it’s easier to talk in terms of horsepower. This usually starts at a quarter or a half a horse.

Larger horsepower pumps (five or six HP) are only used for huge operations.

Most horsepower pumps are inline pumps like pool pumps (which are what we use in our aquaponic and hydroponic systems).

There’s a motor housed separately from the pump housing. This means that the pump can’t be submerged in the water but has to be hooked up outside of your sump tank. A lot of the time there is a skimmer included in the pump.

Submersible vs. inline pumps

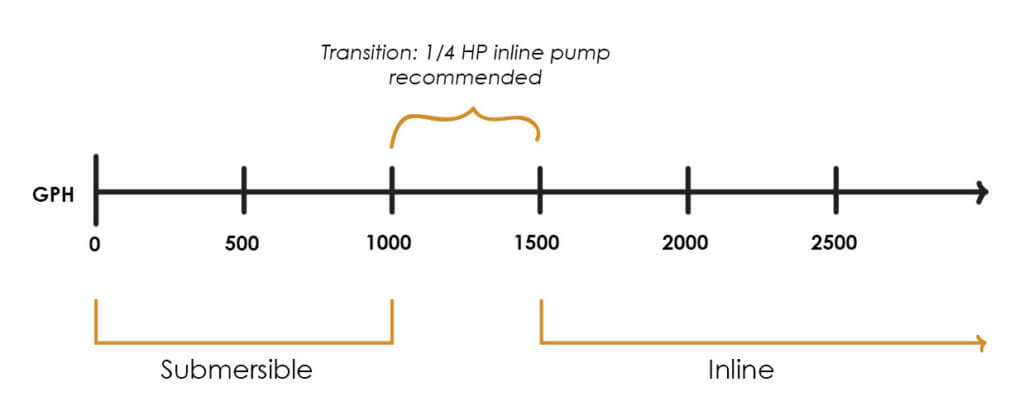

You should be using a submersible at about a thousand or fewer gallons per hours (when your total GPH < 1000). For systems larger than this, you should be thinking about inline pumps.

While inline pumps do tend to be more costly, there are several benefits. They last longer than other pumps and tend to be more durable in general. They don’t run the risk of electrical “leaks” (which can be a problem to fish health if you’re running an aquaponic system) like submersible pumps do.

An additional benefit to inline pumps is the skimmer. Growers should have a filtration manifold including some kind of canister filter (or Y-filter) and UV clarifier, but the additional skimmer can capture large solids, extending the life of both and making maintenance easier.

Where do you get inline pumps?

Pool pumps are well suited for most hydroponic and aquaponic pumps. They’re efficient and rated for the type of operation that hydroponic and aquaponic growers are running.

*Tip from Dr. Nate: Keep an extra inline pump on hand. If your pump goes out for any reason, it could take a couple days to get a new one in. If that happens, your farm could be without water, which equates to a lot of lost product! It’s better to invest an extra couple hundred bucks than lose a thousand.

A good transitional size is 1/4 HP. This is good for small commercial operations or anyone starting a small system that they wish to scale in the future. Almost any other indoor farmer will need a 1/2 HP pump.

We’re fans of Jacuzzi Brothers pumps and Hayward pumps. Both of these are popular brands carried at most pool and hot tub stores.

Submersible water pumps are best for farming purpose,

you may use Either borewell pumps or openwell pumps.

Thank you for timely information and clarification. Now l understand better which pump to look for, for My hydroponics set up.