DIY hydroponic systems have a limit.

We’ve grown great produce with DIY media beds, towers, and NFT systems, but we know that home-built systems have a limit.

In this post, you’ll discover:

- the pros and cons of DIY systems

- the pros and cons of commercial “pre-fabricated” systems

- where to start to choose a production method.

Over the years, the DIY approach served us well, especially on a small scale using half-barrel media beds or 10×10 ft NFT systems.

The benefits started running out, however, once we started building commercial scale systems. With a whole greenhouse full of DIY equipment, we spent weekends fixing leaks, repairing tanks, and troubleshooting. When we switched to pre-fabricated or “turnkey” systems, we got to skip all that and get straight to production.

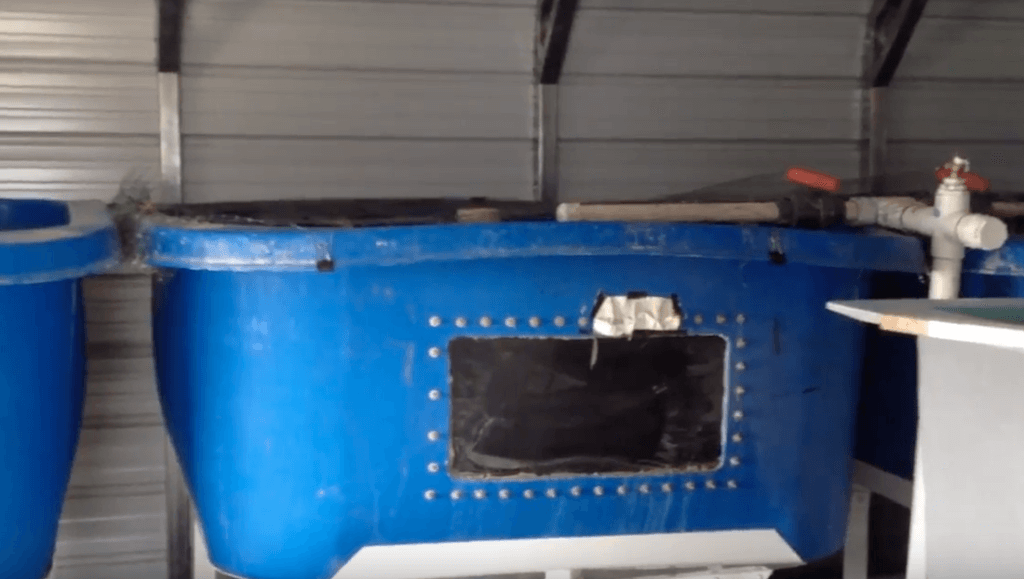

In our first commercial-scale system, we took a DIY approach and put windows in our fish tanks. One Friday night a window popped out, we lost a couple fish and a lot of water, and spent all day Saturday fixing the problem.

When are pre-fabricated systems are better? When should you build a system yourself?

As you might have guessed, the answer to that question depends on several factors:

- Farm size

- Crops

- Budget

- Economics

- Markets

- Time before system has to be functional

Each farmer has unique needs and resources. The wise farmer knows those strengths and weaknesses and chooses a path that will lead them to the best profit!

Let’s compare the two main options.

DIY systems: The good, the bad, and the ugly

Pre-fabricated commercial systems: high CapEx, low OpEx

The main benefit of prefabricated or turnkey systems is that they have been designed and tested for you. This means that they have been through troubleshooting already! The grower saves time on building the system and on long weekends spent fixing leaks and fine-tuning finicky components.

In addition, turnkey systems have clear costs and benefits, which make accounting and funding easier.

Pre-fabricated commercial systems are best for farms that:

- Are heavily used and require efficiency

- Require simple, efficient operation through sophisticated design

- Have little margin for error (because of commercial scale)

- Need to start producing right away

- Are funded by investors who want proof of concept

Turnkey systems are not good for:

- Small scale or hobby farms that aren’t making money. (No ROI.)

DIY systems: low CapEx, high OpEx

The greatest advantage of DIY systems is that they allow growers to have a “test period” to learn the ropes and choose a good system type.

For example, Farmer Rita is learning about business management and types of hydroponic systems so that she can start a farm. She has the right space and resources to do either NFT or media beds. If she wants, she can test out two small DIY systems and learn the specific pros and cons of each system hands-on. She can also use the data from testing to conduct more accurate market and sales research. (Important to projecting revenue!)

When Rita has the experience to choose a system, she can expand into a full-sized system with more cost-effective and labor-efficient turnkey equipment. By this point, she has both the experience and the proof-of-concept to help her secure funding and train new employees.

DIY systems represent one major disadvantage as well, and that is that they are unpredictable. DIY systems are naturally “prototypical” and untested, so growers have to be ready for anything. This means more troubleshooting and frequent repairs. On a small scale, these repairs can be handled. On a large scale, they can cause significant losses in production (threats to your sales) and a lot of labor time.

DIY systems are best for farms that:

- Are operating on a small hobby or experimental scale

- Need to train, learn, and get to know markets with low stakes

- Have plenty of labor and time for unexpected repairs

DIY systems are not good for:

- Commercial scale farms with commitments and high production goals

Using DIY systems for testing

This barrel and tower system is a great size for testing.

Nothing can beat a DIY system when it comes to trying out your options. You can set up a DWC next to an NFT to test production and how hard it is to manage. You can set up two small identical systems to test out regular versus organic nutrients. When the test is over, you can take apart the systems and make an informed decision before making a large commitment to a growing method.

Lots of Upstart Farmers learned the ropes with test systems after choosing a few to test.

Want to get started on testing? First, check out the main five types of grow methods:

- NFT (Nutrient film technique)

- DWC (Deep water culture)

- Aeroponics

- Vertical towers

- Media-based

Dr. Nate describes these methods in the course “Choosing Your Production Model“. If you’re an Upstart University student, check it out. If not, you can get the whole course and others with the free trial! For more tips on getting equipment, check out our Ultimate Guide to Starting a Farm!

Trackbacks/Pingbacks