Balance income from season to season with fertigation

Seasonal demand, changing inputs, and availability of space are just a few factors that can change the growing and selling opportunities for farmers. Farmers ready to take advantage of those opportunities with different crops and grow methods are more successful overall.

Fertigation is one method that can be used alongside other techniques.

Fertigation is one method that can be used alongside other techniques.

Compared to field crops, fertigation offers:

- less evaporation from irrigation

- less water loss from runoff

- higher yield

- better nutrient management

Haydn Christensen at Colorado Fresh Farms (previously known as Bayberry Fresh) ran a two-hoophouse fertigation system for Sweet 100 cherry tomatoes this summer. As we head into autumn here on the east side of the Rockies, we got to take a closer look at how the fertigation system is set up, how it works, and what Haydn will approach differently in the coming year.

See the Colorado Fresh Farm system:

What is fertigation?

Fertigation is the precise application of nutrient solutions (fertilizers) through irrigation.

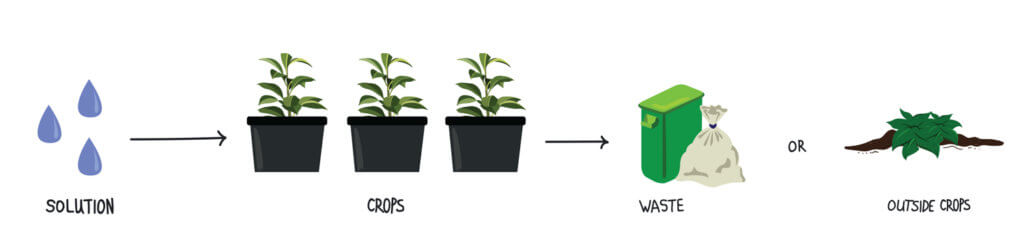

In a contained system, fertigation is similar to run-to-waste hydroponics, where a solution is run once through the media. Instead of recirculating and being adjusted to the right EC and pH range, however, the leftover solution is drained.

Farmers can redistribute the runoff water to other crops (Haydn uses it for his outside crops), but often there isn’t much runoff at all.

In well-sized systems with good media, fertigation can be a perfect match to plant needs. Haydn runs his single pump on a timer to irrigate every two or three hours, depending on the time of the season. Occasionally he gets a small puddle at the end of his irrigation system, but never more than a few gallons.

How does a farmer run fertigation?

Fertigation systems run in a system with media instead of soil and are essentially run-to-waste hydroponic systems; a solution concentrate is kept in a mixing tank (Haydn uses 50-gallon barrels for this) and injected into a sump tank with an injector, which mixes the solution to a certain EC.

The maintenance for fertigation systems can be quite simple: Haydn mixes concentrate every 3–4 days, tops off the water when it starts to get low and does walk-throughs a couple times a day.

Every now and then, a dripper is knocked from the pot or gets clogged. If he’s unlucky, a pump might burn out. Otherwise, system maintenance is largely preventative.

Crop timeline for cherry tomatoes in fertigation

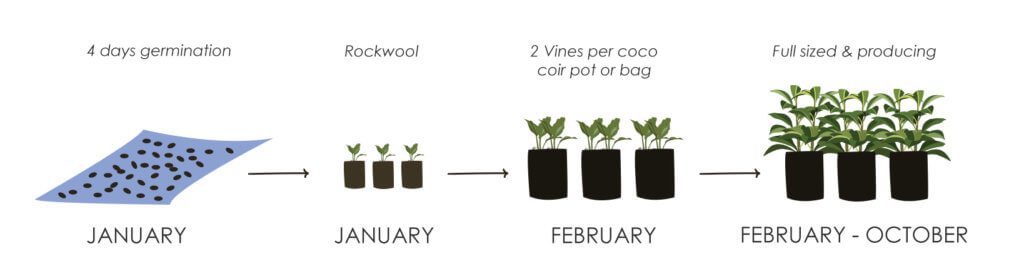

The system set up is fairly simple. In January, Hadyn starts the tomatoes from seed. He leaves the seeds in a damp paper towel in the dark for four days, until they are just beginning to crack. Then he chooses the germinating seeds and plants them in rock wool cubes using tweezers.

The process takes precision, but ensures almost 100% germination rate in the rock wool and reduces his material costs. To plant 800 plants (two hoop houses worth), it takes Haydn 4-5 hours.

While the seedlings mature, Haydn fills his pots or bags (this summer he used both) with media. This is a more time-consuming task and takes him about two weeks to finish by himself. When the seedlings are ready and the greenhouses are warm enough, they are transplanted into the pots and brought into the greenhouse.

The tomatoes are maintained and harvested from February to October. By the end of October, Hadyn has tapered off labor and irrigation and harvested the last of the tomatoes.

Materials and tools

Haydn uses 3-gallon nursery pots that can handle 2 “leaders” (the main vine on a tomato plant). After running an experiment his first year with sand, Haydn settled on the more sustainable and water-holding coco coir as his media.

Following his mantra, “keep it simple”, Haydn sources most of his irrigation supplies from Home Depot. Poly lines and 2 GPH drippers were the staples of the irrigation system.

Tomatoes need a trellising system, which can be built with posts and wire, usually with extra support from the greenhouse. Each wire holds Tomahooks which connect to vine clips for a lean-and-lower system. This system lowers the plant as it grows, maximizing space and cleanliness.

Pricing cherry tomatoes

Each farmer should do some asking around to find the price lists that are most relevant to their area. (Learn more about choosing your markets in this Upstart University course). For Haydn, pricing was based on farmers market pricing found in online survey reports and his own experience.

At the farmers’ market, Haydn sold fresh ripe cherry tomatoes for $3/pint. To the school district, who bought in greater volume, Haydn sold the tomatoes for $30-36 per case depending on the time of the season. During the summer months, he harvested about 35 from a hoop house with 400 plants. By the end of October, that had slowed down to 30 cases.

Haydn suspects that he can increase that yield with improvements on next year’s system and with more streamlined labor.

Why use fertigation over recirculating systems?

Haydn’s choice of fertigation was based on resources, opportunities, and situation. This is a smart way to approach the method decision using these three questions:

1) What unique resources do I have at my disposal?

Haydn was able to source his pots for 10¢ apiece used, and found that he could source coco coir locally. He could outfit his whole greenhouse with fairly low overhead costs.

Haydn also got two used hoop houses and had the land to set them up, so space wasn’t a major limiting factor.

2) What sales and marketing opportunities do I have?

Haydn sold tomatoes primarily to the Boulder School District and at farmers’ markets. Together they built enough demand to make the tomato operation worthwhile.

3) Do I have unique situational constraints or considerations?

Sometimes, you won’t identify unique constraints until the season is ending. This is when it’s smart to plan those considerations into next year’s operation!

Improving the process for next year

Haydn will leave this system up for use next spring and summer. Over the winter, he’ll set up ceiling tresses and a slab/gutter system to collect runoff for use elsewhere. His goal is to keep costs the same, and with building mostly out of the way, he can focus in on maximizing production.

Learning to farm? Get a well-rounded education.

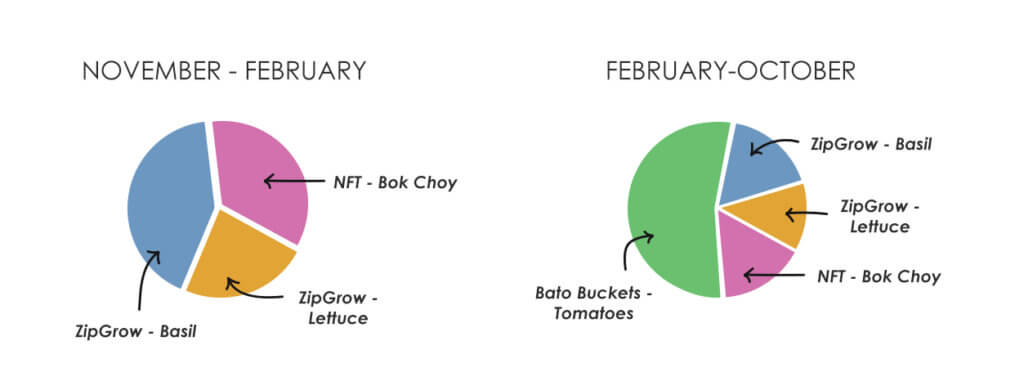

As Haydn shows us, business planning and sales are just as important to a good farm as growing the crops is. Haydn wisely diversifies his income stream and always has a plan for consistent income year round. This is a good way to eliminate risk for any business.

If you’re looking for help on business planning, finding demand for your produce, and managing a small farm business, then look no further; Upstart University has over thirty courses (and counting) tailored especially for small startup farmers.

You can enroll today or try out a 1-week free trial.

Trackbacks/Pingbacks