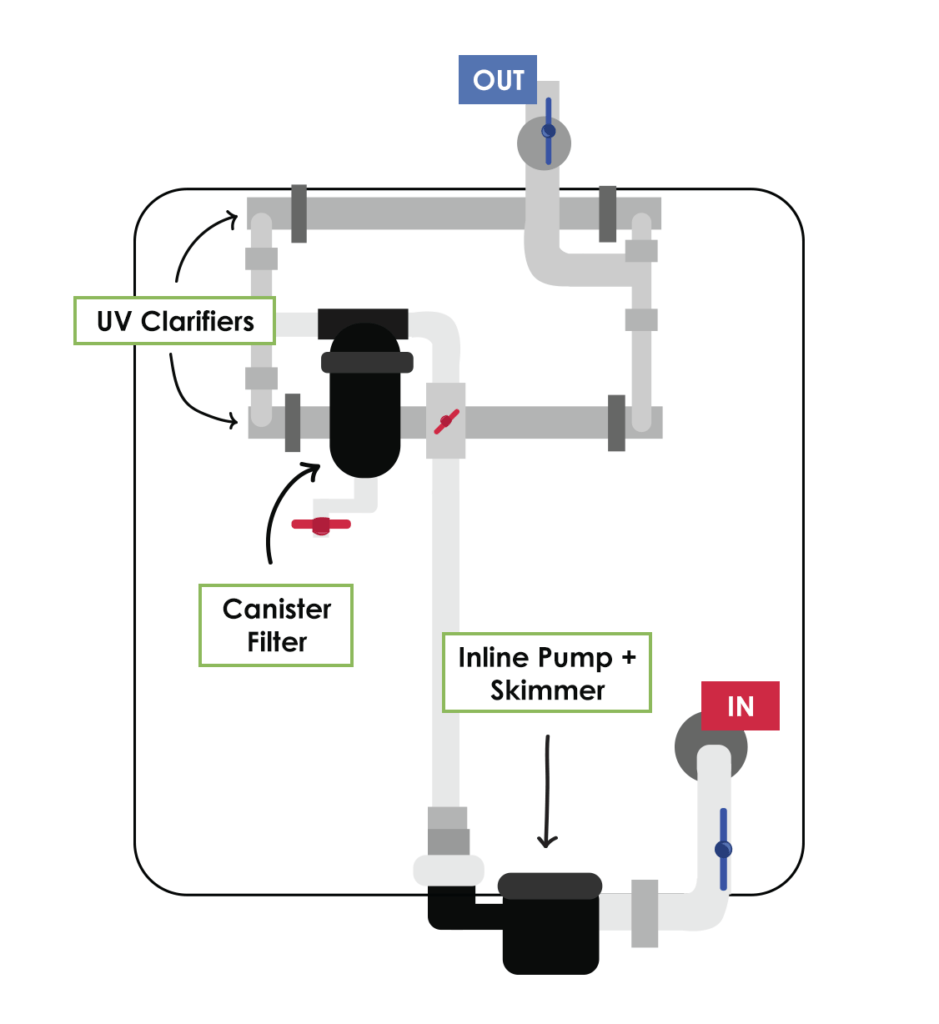

In a closed-loop system, maintaining good water quality is a difficult feat. However, neglecting to sterilize the water that circles through the system can cause fouling and decrease yields. The filtration manifold solves this problem by filtering and clarifying water as it cycles from the return line through the mixing tank and back into the irrigation lines. The purpose of its various components is to capture solids and kill possible pathogens and algae.

If you’re using a ZipFarm, (and even if you’re using a similar hydroponic system), you can use a filtration manifold like this one on your farm. In this video, you’ll see how our filtration manifold is laid out on our mixing tank and how it’s arranged. In this case, we were a bit low on space, so the manifold is configured pretty tightly. You can space it out more if you’d like.

Filtration manifold components & purposes (in order of water flow)

ZipFarms use a closed-loop or recirculating system. The ZipGrow Towers are irrigated with drip lines, the water runs down the towers into the return line, is sent back to the sump and pumped up to the mixing tank directly above it. In the mixing tank, nutrients and pH adjustments are added, then solids and algae are filtered from the water before it is pumped back to the irrigation lines, and the process starts all over again. All of this filtration and movement largely happens in the filtration manifold.

The filtration manifold is composed of 4 main components as well as a few add-ons:

1) Inline pump

The water is pulled out of the tank with an inline pump. We use a Hayward 1/2 HP (horsepower) pump. This is a general purpose pump that is low maintenance (farmers will only occasionally have to clean the skimmer) and delivers a lot of pressure.

Although 1/2 HP is quite oversized for our system, the extra pressure doesn’t do any harm and it allows us to scale up without changing pumps every time. It’s quite affordable, but the downside is that you will have to wire it in yourself. (Just replicate the wiring on the pump you already have.) In our opinion, it’s definitely worth that!

For farmers who are absolutely sure that they won’t scale up that much, a 1/4 HP pump will still offer some scaling potential with all of the same benefits as a 1/2 HP pump.

2) Skimmer

The skimmer is situated inside the pump and does some basic large-particle waste removal. If there is any debris from a potting mix, leaves that have fallen off of crops, etc., the skimmer will collect most of them. Depending on the system and management, the skimmer will need to be cleaned out a few times a month. (We clean out ours every 2 weeks.)

3) UV clarifiers

Once the water is moved from the mixing tank to the inline pump, it is pumped upward and through two UV (ultra-violet) clarifiers. As the name suggests, UV clarifiers use light to perform a kind of biological sterilization, killing any bacteria and algae in the water that moves through them. This will help with algae and pathogen control and can be a helpful addition to your IPM strategy.

We have two clarifiers in our ZipFarm because the water needs to spend a certain amount of time beneath the light to be sterilized, and a good amount of water is moving through the manifold. Larger systems might need more, and smaller systems might only need one. Each UV clarifier will come with specifications regarding how much water can be moved through them in a minute or an hour. Use that number and the gallons per hour you expect to be moving through your system’s irrigation to determine how many clarifiers you will need.

4) Canister filter (Y-filter)

4) Canister filter (Y-filter)

From the UV filters, water moves through the canister filter, which captures the dead algae and small build up. The water is sent into the filter from the top and flows through the screen canister before swirling upward and onward. Like the skimmer, this filter will need to be cleaned regularly; you can do this by back flushing it.

*Note: the Y-filter should come before the UV filter.

Learn how to backflush the canister filter in this video.

Add-ons

There are a few extra bells and whistles you can add to your filtration manifold and plumbing that can improve your capabilities.

The first is a pressure gauge. A pressure gauge helps us spot any pump problems that we might have. If the pressure spikes or (more likely) dips suddenly, we know that we need to take a look at the pump and make sure that it’s functioning properly. This keeps irrigation to crops consistent.

The second is quick connects. We use quick connects on most of the filtration components to make them easy to remove, replace, and clean.

Start building your farm

Join hundreds of students on the quest to provide families and communities with fresh produce from your very own local farm! Make your dream a reality by signing up for an Upstart University membership today!

How is the water from the ziprack flow back to the tank? Do you use pump, and filter that water too?

Hi there! After trickling through the ZipGrow Towers, the solution drains through a return line back to the sump, where the EC and pH are adjusted. Then it is moved through the manifold before being pumped back to the Towers.

Hi,

I really like this setup you have designed. Do you sell this filtration manifold and for how much?

If not is it possible to get/buy the drawings for it?

Hey Ronnie, the filtration manifold is part of the ZipFarm (brightagrotech.com/zipfarm), but the basic layout can be used in many system types. We don’t have formal drawings available right now.

What’s right location of Y filter ?

Water passes thru UV before or after passing thru the Y filter ?

Hi Vivek,

Water should pass through UV after the Y filter.

Hello! This product is just what I need in my zip farm. Where can I purchase it? It is not on your site.

how does a person know how much additional iron to dose after uv?

Hey luke555—

Use 10% chelated iron, dose at a rate of 1 gram iron per 10 gallons in the reservoir. Dose weekly, and turn off UV for 24-36 hours after adding iron.

Awesome thanks! And what micron is the filter membrane?

mainly what brand filter is that trying to source everything?

Would it be more beneficial to put th filter befor the uv clarifies?

Robert—

Yes, we would recommend filtering before UV. The clarifiers work better with clean water.

Where can I buy the canister filter?

Hi Wesley,

You can find them on Amazon as well as in just about any aquarium or pond supply store.

Thankfulness to my father who informed me about this blog, this webpage is really amazing.

Wouldn’t the UV lights kill any beneficial bacteria in the system as well?

Hi Aaron,

Yes, UV lights will kill everything in the system.

Do you have any issue with the quick connect you used for draining? Does it clog? Is the drain tape you are using better than pvc? Your drain tape is flat and not slanted. Do you have issue with nutrient staying in the drain tape or does it completely drain out?

Hi there,

Both the drain tape—or “lay flat tubing”—both had issues with clogging. We do recommend PVC, and we chose different quick connects that had a wider opening.