If you’re considering aquaponics (a form of hydroponics incorporating fish and their waste as fertilizer), then you’ve almost certainly heard of raft or DWC (deep water culture) systems. Aquaponic raft systems have been grandfathered into the industry as one of the traditional aquaponic techniques.

Raft systems are a great option for many people who are:

- living in the tropics or deep South (U.S.)

- dealing with a limited startup budget but cheap labor and space

- hobbyists curious to try out the technique

What is an aquaponic raft system?

In your pursuit of aquaponic excellence through DWC growing, there is one name that you must know: Rakocy.

Dr. Rakocy at the University of the Virgin Islands (UVI) was the first person to develop an aquaponic raft system (or DWC, deep water culture system) on a commercial scale. His success with the large aquaponic raft system has provided data, ratios, and management practices which laid a foundation for growers all over the world.

In an aquaponic raft system, rafts float over water channels and the plants grow from the top of the raft with their roots dangling in the solution below. Like any technique, raft production is suited to particular climates and crops.

So what’s the draw to raft systems?

The pros of raft systems include a low capital investment compared to other aquaponic systems, and their ability to stabilize root zone temperatures. If you’re familiar with plant function, you know that plant roots aren’t built for rapid temperature change, so keeping temperatures steady is key to plant health. Raft systems have a lot of thermal mass in the hundreds of gallons of water in the troughs. This makes it more difficult to change water temperature, and root zone temperatures are kept steady as a result.

On the other hand, raft systems typically don’t cut down labor and are limited to one “layer” of production (stacking troughs is difficult and not usually worth the costs). This impacts space use efficiency, which is sometimes a deciding factor for farmers. Two other important needs of raft systems are the need for aeration*, and for frequent monitoring of pumps**.

The nature of raft systems makes them great for tropical climates. In the tropics, labor is often a marginal cost of production, and the large thermal mass (lots of water = lots of thermal mass) helps to stabilize root zone temperatures in the heat. Tropical climates or climates of the deep South (U.S.) are where DWC truly shines. Other situations where raft systems make sense might have very cheap space, low labor costs, and/or very limited startup costs.

*Aeration is necessary — While shoots produce oxygen, roots consume it. This is why, in dense media types or low-oxygen water, root zones may become anaerobic. If you remember, anaerobic zones can cause disease, plant stress and root death. To avoid that we have to aerate. This is typically done with air stones. In the UVI system, air stones were placed every few feet in troughs.

**Pump failure can be catastrophic — There are definite limits on how long plants can last without water flow (water flow = delivery of oxygen). This is true of almost all growing techniques but is especially concerning in DWC systems, because one failure can mean entire crop loss.

So, what does it take to build a successful aquaponic raft system?

Components of a successful aquaponic raft system

Each part of a raft system plays a crucial role in promoting production, protecting plants and fish, and maintaining environmental quality. There are 6 major components that most raft systems need, based on the UVI system design and ratios.

1) Four 2,000-gallon fish rearing tanks

In any aquaponic system, fish waste powers the nitrogen cycle, culminating in the formation of nitrates, an input of plant production. The UVI raft system implemented a much higher fish-stocking rate than most other systems. In many systems, high stocking density results in solids build up and water quality too poor to be redeemed by the system’s inherent biological and physical components. In the UVI system, this poor water quality was instead redeemed by multiple filtration components: the clarifiers, filter tanks, and degassing tanks listed below.

2) Two 1,000-gallon clarifiers

Most aquaponic systems use a filtration or water quality sequence that involves:

- solids removal

- fine particle filtration

- breakdown and degassing

(Typically in that order.) The clarifier represents the first phase of this sequence and removes solids from the “fish water” flowing from the fish tanks.

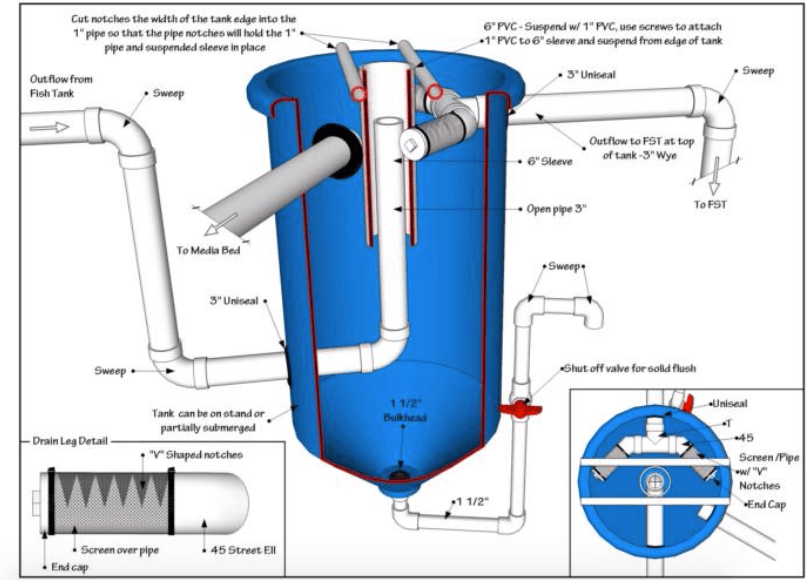

3) Two 185-gallon filter tanks

Filter tanks contribute bio-filtration through a netting material to avoid anaerobic decomposition. This looks like a large drum filled with a netting or mesh material. Microbes populate the copious biological surface area of the material, which catches solids waste and provide a substrate for mineralization.

4) One 185-gallon degassing tank

Degassing tanks remove methane, nitrogen gas, etc. As mentioned earlier, gasses like these are usually only present in high concentrations in systems with very high stocking density. Systems with lower stocking density (for example, ZipGrow aquaponic systems recommend a stocking density of 1 lb fish per ten gallons of water; this is fairly low) do not require degassing.

5) Four 3,000-gallon shallow troughs

The troughs carry nutrient-filled solution to plant roots. 10–12 inches is considered a good depth for the troughs. At this depth, there’s good oxygen diffusion and thermal mass, but troughs are not so deep that growers are moving extra water unnecessarily. The deeper the troughs are the harder it becomes to justify the cost with value delivery.

6) One 160-gallon sump and one 50-gallon base additions tank

From the sump, the water is cycled back to the fish tanks. The base additions tank allows operators to change pH slowly, which helps avoid fish stress.

The ratios from Dr. Rakocy’s UVI system have proved trustworthy and have been used in raft (DWC) design around the world. The ratios are worth following for new growers big or small.

Interested in building your own raft system?

Get the nitty gritty details of aquaponic raft system design!

Aquaponic raft system expert and experienced farmer JD Sawyer (from the Aquaponic Source) recently presented a free workshop on the design and economics of a DWC aquaponic system.

The attendees learned how to:

- Create a basic conceptual design for an aquaponic farm

- Layout fish tanks, filtration and growing systems

- Determine plant and fish production

- Estimate farm revenue and expenses

Want to catch the replay?

Sign up for Upstart University ($9.99/month) to watch this webinar as a course.

When this webinar’s out?

Hi Luis, this webinar is over, but for the same price as the webinar you can get a month of Upstart U, including this webinar and 30 other courses. Check out the memberships here: https://university.upstartfarmers.com/membership-account-levels?ref=2

Hi Amy, how find webinar in my profile course plan?

Thank you, Fabio

Hi Fabio,

The webinar can be found in the Aquaponic DWC course.