Getting started: lighting for vine crops

If you’re new to growing vining crops like tomatoes or cucumber, you’re in for a rewarding journey.

Each farm is unique, and vining crops create some of the most interesting farms. Since many fruiting crops grow high and are trellised into the growing space, vining crop farms create a jungle of plants that can get tough to manage. Over the years, humans have perfected the cultivation of vining crops in indoor environments. We know how to keep them clean, contained, and in supply of everything they need.

One of the most dynamic factors in managing these types of farms is the lighting for vine crops. For indoor vining crop growers, artificial lighting is required. When it comes to choosing, arranging, and maintaining those lights, things get interesting.

In this post, we’re going to discover the basics of light and vining crops, from how plants use light, how vining crops need light to be delivered, and how you as a farmer can choose and manage light for your indoor vining crop farm. At the end of the article, check out the free eBook by LumiGrow explaining the specific lighting requirements for vining crops.

As a quick disclaimer, let me warn you that lighting can get pretty technical. Understanding crop lighting means studying the science of light and how plants use it. I encourage you to stick through the acronyms and numbers to the end, though; mastering light will serve you well as you run your farm.

What is light and how do plants use it?

Light is emitted both as waves and as particles; to be more precise, light is emitted as waves of photons, which are essentially bundles of energy. (A specific number of photons can be measured as a mole, 6.023x 10^23 particles). The amount of energy in each photon determines the length of the wave from crest to crest. While wavelengths can vary from nanometers to meters, plant pigments can only use specific wavelengths.

Most of those useful wavelengths occur between 400 and 700 nm on the spectrum.

Growers should strive to match the needs of the plant as closely as possible with the light while weighing that against other things like cost and efficiency.

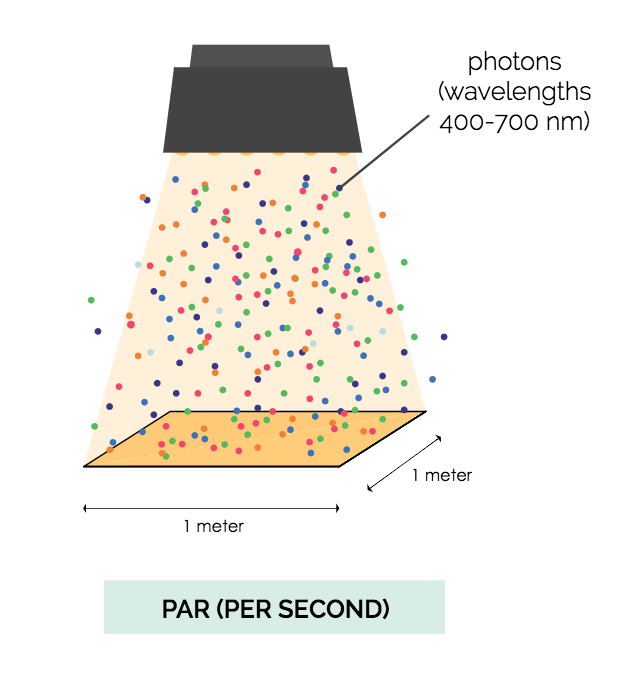

Light efficiency is the amount of light that the plants can use for every watt or kilowatt of electricity that is used. PAR, or Photosynthetically Active Radiation, is the most useful light to the plant.

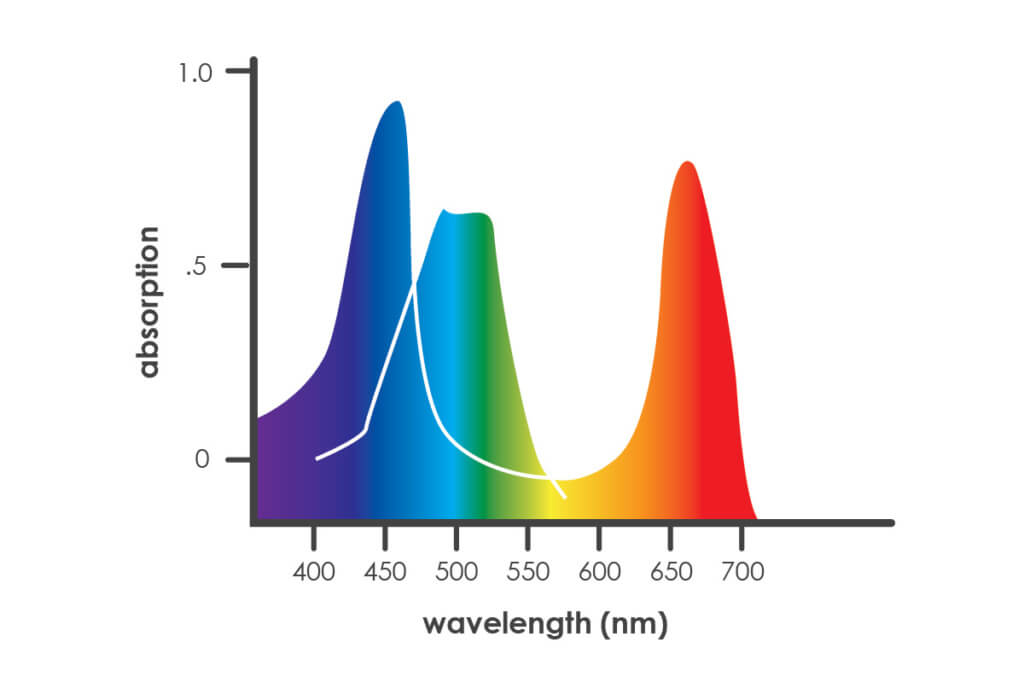

Plant pigments absorb light at specific wavelengths and use the energy in photosynthesis. The three main pigments that you deal with are:

- Chlorophyll a – Absorption peaks at wavelengths around 430 and 662 nm.

- Chlorophyll b – Absorption peaks at wavelengths around 453 and 642 nm.

- Carotenoids – Absorption peaks at wavelengths around 450 to 454 nm.

The most absorbed wavelengths occur around 450 and 660 nm.

Now that you understand the basics of light, let’s take a look at the next critical step – measuring light. Every farm manager needs to understand light measurements to calculate the light needs for their farm. Light measurements are also a key factor when choosing lights, and lighting specs and buyers guides often include measurements like DLI and PAR to describe the power of the lighting equipment.

Looking for more info on lighting your farm? Check out the Lighting for Farmers Course here at Upstart U.

3 ways to measure lighting

There are three measurements that you’re likely to see on spec sheets, in conversations with lighting manufacturers, and buying guides. Those are PAR, PPFD, and DLI. Other measurements, like lumens, work for non-grow lighting but aren’t helpful for the average farmer.

PAR (measured in micromoles/sec-m2) is the measure of the photosynthetically active radiation, or the useful light energy (for plants) at a given point in space. A PAR measurement by itself is of little use, but knowing where the measurement is being taken relative to the light will give you an idea of the intensity. Some LED companies do a great job of displaying charts with PAR measurements at various points (coverage at different heights). This is the best information you can get.

PAR (measured in micromoles/sec-m2) is the measure of the photosynthetically active radiation, or the useful light energy (for plants) at a given point in space. A PAR measurement by itself is of little use, but knowing where the measurement is being taken relative to the light will give you an idea of the intensity. Some LED companies do a great job of displaying charts with PAR measurements at various points (coverage at different heights). This is the best information you can get.

PPFD (measured in micromoles/sec-m2) stands for photosynthetic photon flux density and is a measure of the truly useful photons within PAR when the exact spectral composition is known. PPFD measures only the usable portions of PAR, so it functions like an efficiency rating on PAR.

DLI (daily light integral), is the real-life translation of PAR (photosynthetically active radiation) or PPFD values into actual growing time. A grower may know how much light at certain wavelengths is hitting a square meter every second. But how many seconds of that light does the plant need? That’s the question that DLI answers.

DLI is measured in mol·m-2·d-1. Notice that DLI is measured in similar units as PAR, only in the context of one day. For example, 12-14 mol·m-2·d-1 is the recommended DLI for lettuce production in greenhouses and even higher DLI values (15-20+) are required for fruiting crops.

Vining crops and light

Vining crops require special consideration when choosing light for two reasons: they are fruiting crops (optimized for reproductive growth), and they grow in vertical configurations (indeterminate varieties allow for trellising and efficient space use).

Many LED fixtures like this LumiGrow Pro 325 allow farmers to adjust the blue:red light ratios.

Light and reproductive growth

Far-red light (700+ nanometers) in reproductive growth is useful mostly for triggering flowering. It’s also used for some photosynthesis in the lower canopy. In natural settings, far-red is indicative of the angle of the sun.

Day length plays a major role in the reproductive growth and if you use far-red light to trigger reproductive growth, you must pair it with the correct day length.

Light and vining crops

Vining crops typically grow tall up a trellis (most growers look for indeterminate varieties over bushy varieties). Some crops, like tomatoes or hops, can grow to be over twenty feet tall during a long season. Others like cucumbers and pepper still reach six or ten feet. This means that lighting requirements can be different for vining crops than for small statured crops like lettuce. Vining crop growers can use either top lighting or inner-lighting or combine artificial lighting with natural lighting in a greenhouse setting. Each situation is different depending on the farm needs.

Inner-lighting for vining crops

Inner-lighting is a configuration which requires that lights are hung between plants rather than over them. The challenges of inner-lighting are that with lights hung between curtains of plants, either wide light angles or light movers (on tracks) are required to distribute light evenly, and heat can build up if the configuration is too dense. These challenges are solved several ways: first, growers opt for light bars rather than boxes or panels. Second, LED lights are used rather than the less efficient HID or HPS.

Have more questions about lighting for vining crops?

Vine growers still have several decisions to make. How many lights are required for their operation? Which LED lights will deliver the proper amount of light and the right red to blue ratio?

To answer some of these residual questions, the folks over at LumiGrow recently published a guide to lighting vining crops with LEDs. We recommend picking up the guide for free here.