Hydroponic nutrients are at the core of good management

Hydroponic systems can conserve more water and represent huge efficiencies because they are water-based; that is, they use water as the main delivery method of plant nutrients.

Because nutrients are more directly available to plants, hydroponic systems can eliminate bottlenecks to production that are involved in nutrients. This increases the growing capacities of these types of systems.

It also makes nutrient management the crux of a well-run hydroponic system. So what exactly, does nutrient management entail?

Great hydroponic nutrient management occurs when growers are:

- Informed about plant nutrients and where they come from

- Supplying adequate amounts of nutrients to plants

- Supplying the correct ratios of nutrients to plants

- Monitoring and measuring each plant nutrient at any given time

- Making economic and workflow conscious decisions about nutrients

This overview will prepare growers to start achieving all of these goals! We’re going to walk you through plant nutrient needs, how to measure and monitor, and the factors of making wise fertilizer choices.

Watch the video:

The 16 plant nutrients and where plants get them

Most plants (and all of the crop plants that you’re likely to grow) rely on 16 nutrients to grow and reproduce. Of these, three are available through water uptake and gas exchange (the air): Carbon through CO2, hydrogen, and oxygen. Growers should be thinking about air movement and dissolved oxygen levels in water, irrigation timing, etc., but generally, these practices are considered separately of hydroponic nutrient management.

The remaining thirteen nutrients are the mineral nutrients delivered to plants through hydroponic nutrients dissolved in a solution. We can separate them into 3 groups:

- Primary macronutrients, the most abundant building blocks in plant growth and reproduction.

- Secondary macronutrients, which are also necessary, but in smaller amounts.

- Micronutrients, which are required in very small quantities for growth and reproduction.

Primary macronutrients: N, P, K

The primary macronutrients are nitrogen, phosphorus, and potassium, or NPK.

Nitrogen is important for all kinds of molecules involved in photosynthesis and protein creation. It is supplied either all at once as in liquid fertilizers, or in two parts (an NPK mix and CaNO3) as in dry fertilizers.

Phosphorus is especially important to cell membranes and is supplied in the main nutrient mix, whether dry or liquid.

Potassium is key to signaling compounds used in plant growth and development in all stages, and like phosphorus is delivered in the main nutrient mix.

Secondary plant nutrients: Ca, Mg, S

The secondary plant nutrients are calcium, magnesium, and sulfur.

Calcium is important to cell walls and is an important structural element. Calcium which interacts uniquely with other nutrients, is much less soluble than the other nutrients, and can cause precipitation (when dissolved solids recombine to create solids in a solution). This means that it must be mixed separately. It is supplied in calcium nitrate, CaNO3.

Calcium is important to cell walls and is an important structural element. Calcium which interacts uniquely with other nutrients, is much less soluble than the other nutrients, and can cause precipitation (when dissolved solids recombine to create solids in a solution). This means that it must be mixed separately. It is supplied in calcium nitrate, CaNO3.

Magnesium is important to the photosynthetic complex, and is supplied in magnesium sulfate, MgSO4, also known as Epsom salt, as well as the main nutrient mixture.

Sulfur is important in peptide bonds, which are present in all kinds of biological molecules. It is primarily delivered in MgSO4 alongside magnesium.

Micronutrients

The micronutrients are:

Without any one of the micronutrients, the plants will die or survive for only a generation or two.

When plants produce seed, there is enough of some micronutrients in the seed to supply the plant that grows from the seed for all its life. But if that plant doesn’t acquire any of that micronutrient when it, in turn, is making seeds, then the next generation will be deficient and die.

Measuring nutrients with EC

The overall nutrient level in a solution is measured in EC or electrical conductivity.

EC measures how well a solution transmits electricity. This works because:

- All mineral nutrients are salts and dissolve to become ions in a solution.

- Ions in a solution make it more conductive.

So when we measure the conductivity of a solution, we are effectively measuring the nutrients in that solution.

An EC meter uses two metal probes to measure conductivity. A current is passed from probe to probe in the water and the strength of that current is measured, then translated into a measurement of how many salts are in the water.

The units used to measure EC are ppm or mS/cm, although ppm is used more commonly for measuring total dissolved solids. Hydroponic growers really need to understand the second unit, mS/cm. This is often just expressed as the “EC level”. For example, “The EC of the solution is 1.8,” with no unit.

Ideal mS/cm values are typically between 1.2 and 3.3. There’s a broad range of acceptable EC levels, and each crop has an ideal range. To find a range where all of your crops overlap, check out the Recommended Crop List or the EC Poster, which list the ideal EC for crops.

Nutrient ratios & formulas

All fertilizers are formulated in certain ratios. Different crops and crop types require nutrients at specific ratios. Using the correct ratio helps growers to avoid deficiencies or toxicities, and keep nutrient solutions balanced over time.

For example, here is the formulation for Chem-Grow’s Lettuce Formula:

- Total Nitrogen (N)…………………………………………8.00%

- Nitrate Nitrogen………………………………..………….7.50%

- Ammoniacal Nitrogen……………………….………….0.50%

- Available Phosphoric Acid (P205…………………15.00%

- Soluble Potash (K20)…………………..……………… 36.00%

TRACE ELEMENTS

- Boron as (B) ………………………………………………….0.20%

- Copper as (Cu)……………………………………………… 0.02%

- Iron (Chelated) as (Fe).. ………………………………….0.40%

- Total Manganese as (Mn)………………………………..0.20%

- Soluble Manganese as (Mn) ……………………………0.20%

- Molybdenum as (Mo) …………………………………..…0.01%

- Zinc as (Zn)………………………………………………..…….0.05%

- Chlorine as (Cl), not more than………………………. 2.00%

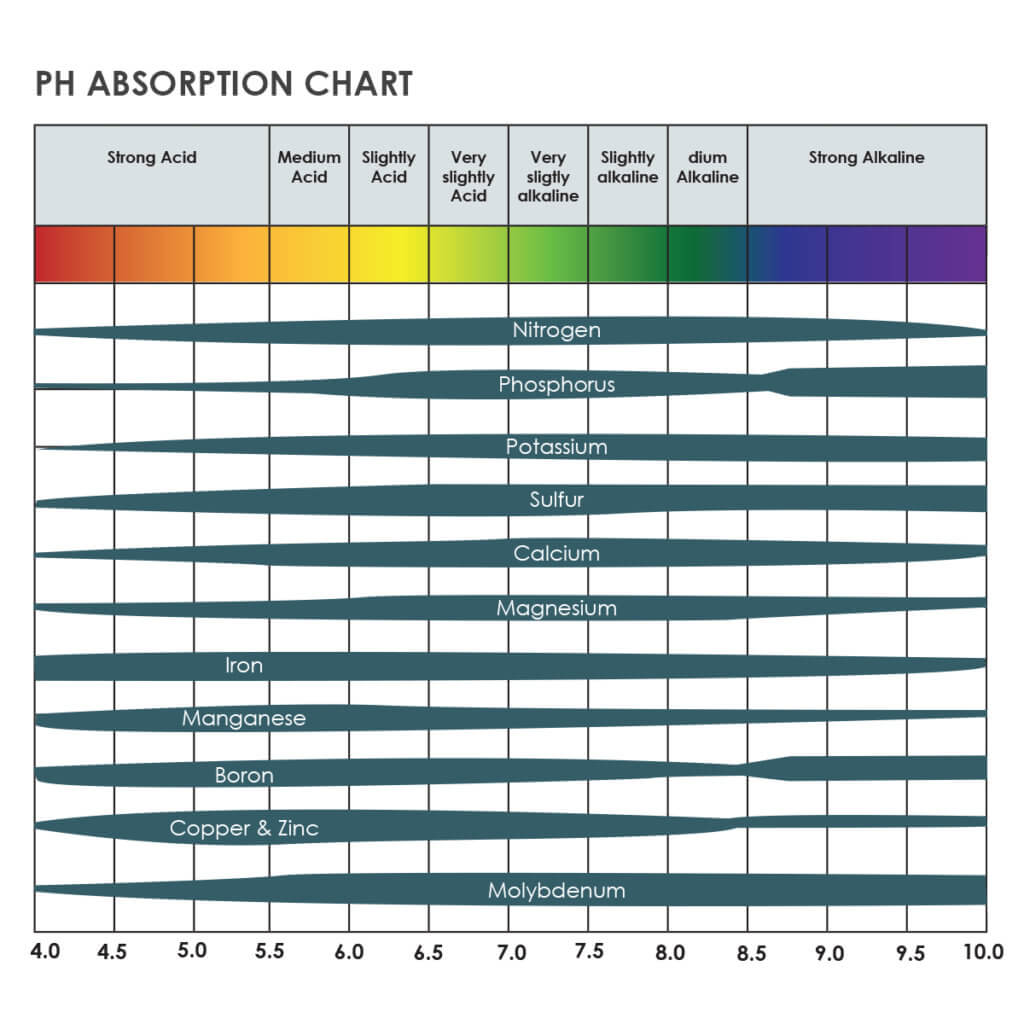

Nutrient availability based on pH

Supplying the correct nutrients is only half of the nutrient management picture; the other task for farm managers is to keep those nutrients available to plants, and the main factor influencing that availability is pH.

Nutrients are soluble at different pH values.

Here’s a graph to help you see this:

Optimal pH is usually between low 5’s and low 6’s. Some crops prefer it a bit higher or lower, so you’ll have to check your crop. (The Recommended Crop List also lists pH ranges.)

Adjusting pH to your ideal range can be done with pH Down or pH Up, which are acids or bases (respectively). There are a few important rules to follow when it comes to pH adjustments:

1) Don’t use both an acid and a base at once or you’ll just be fighting yourself. It’s counterproductive!

2) Don’t use crazy additives like lemon juice or vinegar. Use commercially proven products. If you must use something else, please email us first so we can steer you away from potential costly mistakes!

Types of fertilizer: dry vs. liquid

There are two main forms of fertilizer: dry and liquid.

Dry fertilizer is mostly used in commercial settings because there’s a lot less to ship (you’re not shipping water), making it more cost effective. You can also tailor dry fertilizer better to your needs because it comes in separate parts.

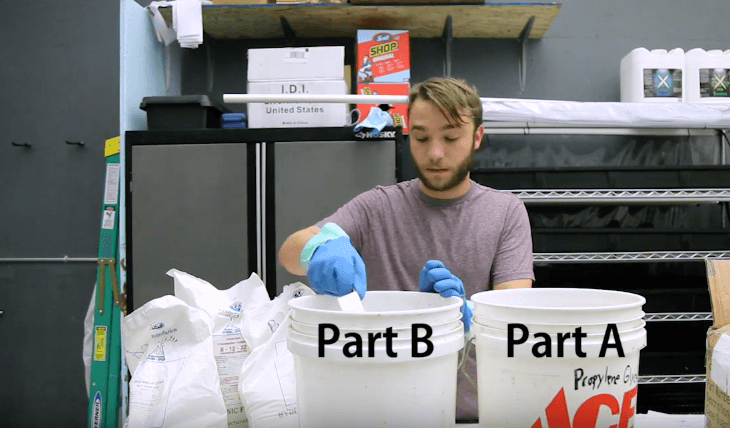

Dry fertilizer usually comes in 1, 2, or 3 part mixes. We use a 3 part mix:

Part A is NPK, most of the macro- and micronutrients—basically all of the salts that dissociate easily and are very soluble.

Part B is calcium nitrate (CaNO3), and the main source of both calcium and nitrate. It’s not very soluble so we keep it and mix it separately.

Part C is magnesium sulfate (MgSO4), and the main way that we supplement sulfur in our system. This is also called Epsom salt and is very soluble.

More complicated fertilizers are available and can come in ten- or more-part mixes. The questions you need to ask yourself are whether using a many part mix increases your production, whether it reduces costs, and whether that increase/decrease is worth the extra labor and space that goes into storing and mixing those complicated solutions.

Liquid fertilizer is simple to use and great for home and hobby systems. It’s easier to manage since you can just add a certain amount of one liquid to your system water, but it’s more expensive to ship. (Most people on a small scale only buy a little at a time though, so shipping is less important.)

Mixing solutions

The best way to mix a solution is to follow the manufacturer’s instructions.

The manufacturer will always send mixing instructions, and this is the best place to start. Over time you can tweak the process a bit for your specific crop and situation.

For example, we’re currently using a Chem-Grow fertilizer to grow strawberries in our hydroponic farm. Chem-Grow’s instructions say to use .375 lbs of both part A and B, and .25 lbs of part C for every 100 gallons of water. So we measure out all of those fertilizers and set them to the side. We mix part A and C together and B separately. (Always mix CaNO3 by itself. Parts A and C can be mixed either separately or together.)

Since we’re using an IntelliDose auto-dosing system, we hook those buckets up to the system, which pump the right ratios of nutrients into the main solution.

If you’re not using an auto-doser, you’ll still mix it the same way, but you’ll add it to your system bit by bit in equal ratios and test it until it’s at the right level. You’ll get better and better at this over time.

Note: Monitoring is extremely important if you’re hand dosing. Measure EC and pH before and after dosing.

Hydroponic nutrient tools

There is a multitude of handheld measuring devices and testers. Our favorite suppliers are Blue Lab, Hanna Instruments, and AutoGrow. We’ve used each of these and are currently using AutoGrow’s NutriTest, a handheld meter which measures both EC and pH with the same device. There are a variety of options out there.

In conclusion: get an edge on hydroponic management

You’ve learned about the 13 mineral nutrients, measuring EC and pH, types of solutions, mixing solutions, and tools to manage nutrients. This should put you on the right road to being a great hydroponic manager.

Of course, there’s always much more to learn!

To learn in depth about the chemistry, storing, and management practices necessary in a commercial hydroponic system, see the Hydroponic Nutrients & Fertilizers course on Upstart University.

Dear thank yuo so much for valuble information about hydroponic

I suggest if there is online course about hydroponic and aquaponic production.

with best wishes

Dr. Khaled Nasser Alredhaiman

Hi, there actually are courses on hydroponic and aquaponic production here at Upstart U! Check them out in the “courses” tab above. (There’s a free week trial if you aren’t a member.)

I have a question:

what is the proper Macro-Secondary-Trace element ratio, whether in hydro or in soil?

Also, Silica (Si) should be included in a list of 4 secondary nutrients, with Ca, Mg and S. Outdoors it is everywhere because of sand dust, however indoors it is usually absent.

HI!

I am interested to know the specific hydroponic nutrient requirement for each vegetable crop as per their specific plant growth stages. EX: lettuce, spinach, basil, mint, kale, etc. I am looking at average for leafy greens but all I’m finding is for lettuce.

Realy a helpfull articles for Beginner’s. We need to understand the basics things for hydroponics farming.

how many ml of nutrient solution we can use for per plant and which step of hydroponic

Hello Jyoti,

Hydroponic nutrients are not typically dosed on a per plant basis, they are dosed based on total volume of water in the system. Mix up the correct ratios before adding them to your system.

Hello Dear Sir/Madam

Thank you for your really helpful info, I was wondering if you could guide me more about PH absorption chart since it’s not clear for me that for example adding manganese to water and as the chart says water must be in strong acid range will it damage my planets since the ph must be in 6.5 range

Reza—

The pH range shown on the absorption chart (5.8-6.5) is the recommended range for both plant health and optimum nutrient availability. It will not harm typical hydroponic crops.

What the ratio of water and nutrients used in hydroponics solution and what the quantity of used nutrients ? Please tell me.

Thanks for nice explanation, does all the plants need same composition of nutrients? E.g. if i want to grow a stwarberry plant vs paper or tomoato will the solution with same composition work or it may have impact on plants growth.

Hi Vishal,

Different types of plants do need different types of nutrients. However, plants like tomatoes and strawberries will have better luck with the same nutrient composition than, say, strawberries and lettuce sharing a nutrient composition.

Hi there,

I am interested to know the specific hydroponic nutrient requirement for each vegetable crop as per their specific plant growth stages.

I there any information table on this as I tried to get info from internet but what I got is only for tomato.

Hope you can help me on this.

Thank you

Earl

Hi there !!

Nice explanation but can you please explain for lettuce nutrient solution there are main three nutrients, NPk, cano3 & mgso4. what is the mixing value gram per liter or gram per gallon to get desired Ec value as for lettuce 0.8- 1.2, so suppose to achieve 1.2 Ec value what is the ratio of all three nutrients which collectively would be 1.2.